How to Choose the Best Replacement Wheels for Factory Carts

Factory cart wheels are essential for keeping manufacturing operations running smoothly. When wheels wear out, they can disrupt workflows, create safety hazards, and increase physical strain on workers. Replacing damaged or worn wheels with the right replacements is a cost-effective way to reduce downtime, improve efficiency, and extend the lifespan of your carts.

Why Replace Worn Factory Cart Wheels?

Over time, factory cart wheels experience wear and tear from heavy loads, frequent use, and rough surfaces. This can lead to issues such as:

Reduced Performance

Worn wheels may make carts harder to push or pull, increasing the risk of worker injuries.

Safety Hazards

Damaged wheels can cause instability, leading to accidents or spills.

Operational Downtime

Faulty wheels may slow down production lines or require frequent repairs.

Replacing wheels before they fail completely keeps workflows seamless and prevents small issues from escalating into costly problems.

Common Factory Cart Wheel Failures & How to Prevent Them

Factory cart wheels endure heavy use and wear, which can lead to various types of failures. Understanding these common issues is key to selecting the right replacement wheels and minimizing downtime in your operations. Here are some of the most frequent causes of wheel failure and how they can be avoided:

1. Bearing Wear & Tear

Over time, wheel axle bearings can become clogged with dirt or worn out from constant use, causing the wheels to slow down or seize up. Choosing wheels with sealed or shielded bearings helps prevent contaminants from affecting performance and extends the lifespan of the casters. Regularly cleaning and lubricating bearings is also crucial in keeping them functioning smoothly.

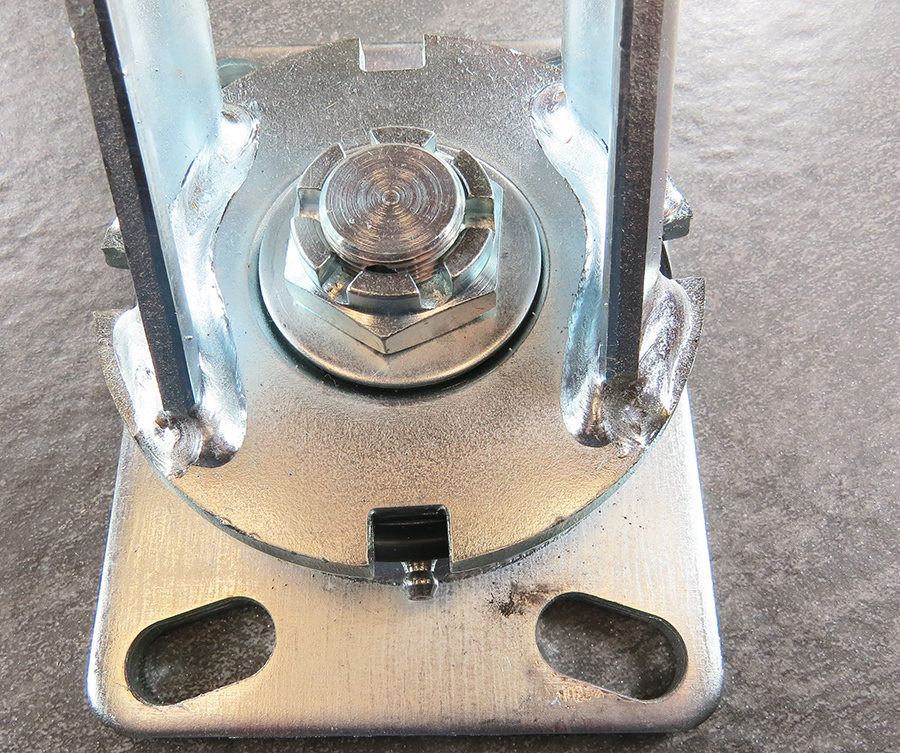

2. Kingpin & Raceway Damage

Casters with traditional kingpin designs can suffer from damage to the kingpin or raceway, which compromises the wheel's ability to swivel properly. This is especially problematic in high-turnover environments, where carts have little downtime and heavy loads are common. Switching to kingpinless casters can help eliminate this issue and improve overall durability, providing a smoother and more stable operation.

3. Flat Spots & Uneven Wear

If factory cart wheels are constantly overloaded or not properly aligned, they can develop flat spots, causing uneven wear that impacts performance. Regularly inspecting your wheels and ensuring that they are used within their weight capacity can help prevent this. It's also important to ensure proper wheel alignment to distribute weight evenly and avoid premature failure.

4. Cracking & Surface Damage

Exposure to extreme temperatures, harsh chemicals, or abrasive surfaces can cause factory cart wheels to crack or deteriorate. Choosing the right material, such as high-strength polyurethane or thermoplastic rubber, is crucial for environments that face these challenges. For example, polyurethane wheels are ideal for smooth floors, while steel or rubber wheels are better for uneven or rough surfaces.

By understanding and addressing these common wheel failures early, you can select the right replacement casters and wheels for your factory carts, ensuring they perform at their best and reducing the need for frequent replacements.

How to Choose Replacement Wheels for Your Carts

Selecting the right replacement wheels requires understanding the unique needs of your operation. The wrong choice can result in poor performance or a shorter lifespan for your carts. Consider these critical factors when making your selection:

- Load Capacity: Choose wheels designed to support the maximum weight your carts carry without compromising maneuverability.

- Material Compatibility: On smooth floors, high-quality polyurethane wheels minimize noise, resist debris buildup, and protect the surface from wear or damage. For rougher conditions, cast iron or steel may perform better.

- Environmental Factors: Consider wheels that resist extreme temperatures, chemicals, or moisture to suit your factory environment.

Consulting a specialist or referring to manufacturer guidelines can help you select the ideal wheels for your carts.

Maximizing Wheel Lifespan with Proper Maintenance

Once you’ve chosen the right replacement wheels, routine maintenance is essential to ensure they deliver long-term performance and reliability. Start by implementing a regular inspection schedule to check for signs of wear, such as cracks, flat spots, or misalignment. Catching these issues early can prevent more significant problems down the line.

Proper lubrication of bearings and axles is another key step. This reduces friction, ensuring smoother wheel rotation and preventing unnecessary strain on both the wheels and the cart frame. Additionally, always confirm that axles and brackets are securely fastened and correctly aligned to avoid uneven wear or instability.

Avoid overloading carts beyond the recommended weight capacity, as this is one of the leading causes of wheel failure. Ensure that wheels are matched to the demands of your workplace, particularly if your environment involves exposure to chemicals, moisture, or extreme temperatures.

By proactively maintaining your wheels, you’ll not only extend their lifespan but also improve safety, reduce operational downtime, and save on replacement costs, ultimately enhancing workplace efficiency.

Shop Replacement Casters & Wheels for Factory Carts

Caster Connection offers a wide selection of replacement casters and wheels designed for a variety of MRO (Maintenance, Repair, and Operations) needs. Whether you’re looking to replace worn-out wheels on carts, trolleys, or other industrial equipment, we provide durable, high-performance solutions suited to various environments, including manufacturing, material handling, and more. Our casters come in multiple sizes and materials, ensuring the perfect fit for your specific applications. From factories and warehouses to specialized environments, we’ve got the right caster or wheel to keep your operations running smoothly.

Browse our collection to find top-quality products designed for longevity and reliability, reducing the need for frequent replacements and enhancing overall efficiency.

SKU: CC-1210-600200-40-T1

ALT-SKU: CCAPEX-6S

-

- Overall Height

- 7-1/2"

- Wt. Capacity

- 1,000 lbs.

- Wheel Width

- 2"

- Wheel Diameter

- 6"

SKU: CC-1010-600200-40-T1

ALT-SKU: CCAPEX-6R

-

- Overall Height

- 7-1/2"

- Wt. Capacity

- 1,000 lbs.

- Wheel Width

- 2"

- Wheel Diameter

- 6"

6" CC Apex Kingpinless Swivel Caster

SKU: CC-2110-600200-40-T1

ALT-SKU: CCAPEX-6S-KP

-

- Overall Height

- 7-1/2"

- Wt. Capacity

- 1,000 lbs.

- Wheel Width

- 2"

- Wheel Diameter

- 6"

8" CC Nexus Maintenance-Free Swivel Caster with Built-In Brake - 4" X 4-1/2" top plate

SKU: CC-3415-800200-40-T1-BIB

-

- Overall Height

- 10-1/8"

- Wt. Capacity

- 1,750 lbs.

- Wheel Width

- 2"

- Wheel Diameter

- 8"

8" CC Nexus Heavy Duty Rigid Caster - 4-1/2" X 6-1/4" top plate

SKU: CC-1115-800300-40-T2

-

- Overall Height

- 10-1/8"

- Wt. Capacity

- 2,625 lbs.

- Wheel Width

- 2"

- Wheel Diameter

- 8"

8" CC Nexus Kingpinless Swivel Caster with Extended Swivel Lead - 4" X 4-1/2" top plate

SKU: CC-2215-800200-40-T1

-

- Overall Height

- 9-1/2"

- Wt. Capacity

- 1,750 lbs.

- Wheel Width

- 2"

- Wheel Diameter

- 8"

10" X 3" CC APEX HD RIGID CASTER

SKU: CC-1020-010300-40-T2

ALT-SKU: CCAPEXHD-1030-R

-

- Overall Height

- 11-1/2"

- Wt. Capacity

- 3,000 lbs.

- Wheel Width

- 3"

- Wheel Diameter

- 10"

10" X 3" CC APEX HD SWIVEL CASTER

SKU: DC-5320-010300-40-T2

ALT-SKU: CCAPEXHD-1030-S

-

- Overall Height

- 11-1/2"

- Wt. Capacity

- 3,000 lbs.

- Wheel Width

- 3"

- Wheel Diameter

- 10"

8" CC Peak Heavy Duty Maintenance-Free Swivel CC Nylex Caster

SKU: CC-4330-800200-40-T2

ALT-SKU: CCNYLEX-MF-8S-TP2-OH2

-

- Overall Height

- 10-1/8"

- Wt. Capacity

- 2,000 lbs.

- Wheel Width

- 2"

- Wheel Diameter

- 8"

8" CC Peak Maintenance-Free Swivel CC Nylex Caster w/ Built-In Brake

SKU: CC-3330-800200-40-T1-BIB

ALT-SKU: CCNYLEX-EMF-8S-OH2-BIB

-

- Overall Height

- 10-1/8"

- Wt. Capacity

- 2,000 lbs.

- Wheel Width

- 2"

- Wheel Diameter

- 8"

8" CC Peak Maintenance-Free Swivel CC Nylex Caster w/ Extended Swivel Lead

SKU: CC-3230-800200-40-T1

ALT-SKU: CCNYLEX-EMF-8S-EXT

-

- Overall Height

- 9-1/2"

- Wt. Capacity

- 2,000 lbs.

- Wheel Width

- 2"

- Wheel Diameter

- 8"

Get Expert Advice on Factory Cart Casters & Replacement Wheels

Replacing factory cart wheels doesn’t have to be a hassle. Whether you’re dealing with heavy loads, uneven surfaces, or high-traffic areas, choosing the right wheels can transform your operations. At Caster Connection, we specialize in helping businesses find ergonomic and durable solutions tailored to their needs.

Ready to upgrade your cart wheels? Contact us for personalized recommendations and support.

Book A CC CHAT Consultation

Need a Custom Caster Solution for Your Facility?

Try CC CHAT (Caster Health Assessment Tour), our free consultative service that provides you with customized solutions for improving your mobility efforts and products.