Why Polyurethane Wheels Outperform Steel in Fabrication and Staging Zones

Heavy loads, floor debris, and uneven surfaces make fabrication and staging zones some of the toughest areas for carts in manufacturing, and modular home plants are no exception. Wheels in these zones need to navigate over bolts, weld spatter, floor seams, and other surface imperfections without slowing production or causing damage. While steel wheels have a long-standing reputation for durability, they often create more problems than they solve. Polyurethane wheels provide the same load-handling strength while protecting floors, reducing noise, and absorbing shocks that can wear down both equipment and operators.

Here are some of the key advantages polyurethane wheels offer over steel in fabrication and staging zones.

Floor Preservation

Steel wheels can chip, scratch, and wear down concrete or epoxy-coated floors, leading to costly repairs and potential safety hazards. In staging areas where products may wait before moving to the next phase, that damage can also collect debris and make the floor harder to clean.

Polyurethane wheels protect floors by providing a softer contact surface that distributes weight more evenly. This floor-friendly quality is especially important in high-value areas such as finish booths or wet rooms, where maintaining a smooth, clean surface is essential for quality control and safety.

Noise Reduction

When steel wheels roll across a hard factory floor, they create a constant metallic clatter that adds to the background noise of tools, machinery, and ventilation systems. Many facilities are required to keep noise levels below certain decibel thresholds to protect worker hearing.

Polyurethane wheels absorb vibration and reduce that metallic impact sound, resulting in quieter operation. Lower noise levels make it easier for workers to hear instructions, alarms, and warnings, and they help maintain compliance with workplace noise regulations.

Shock Absorption

Fabrication and staging zones are not always smooth. Small bolts, weld spatter, and seams between floor sections can cause jolts and sudden impacts. Steel wheels transfer these shocks directly to the cart and its load, which can damage sensitive materials such as glass panels, finished cabinetry, or painted modules.

Polyurethane wheels act as a cushion, absorbing much of the impact and protecting both the load and the operator. This extra layer of protection reduces the risk of product damage and helps minimize operator fatigue during long shifts.

Ergonomics and Safety

Steel wheels require more force to start rolling and keep in motion, especially when carrying heavy loads across uneven surfaces. This higher push/pull effort can increase strain on operators, leading to fatigue and a greater risk of workplace musculoskeletal injuries.

Polyurethane wheels roll more easily thanks to their softer tread and low rolling resistance. This makes it easier for operators to move heavy equipment, even when rolling over debris or uneven floors, improving comfort, reducing strain, and supporting a safer work environment.

CC Apex: The Top Wheel for Fabrication and Staging Zones

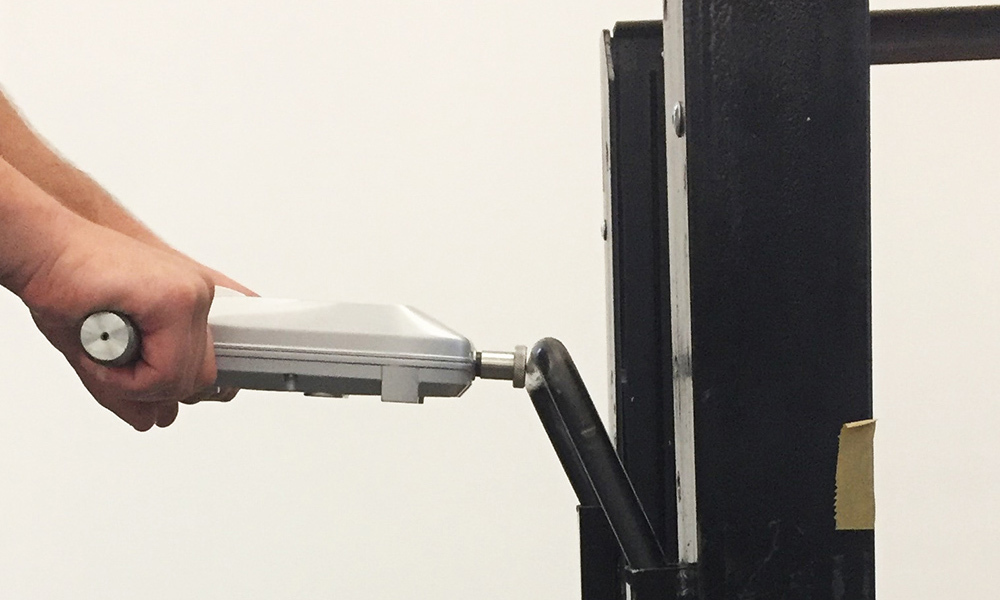

For the best performance in demanding environments, we recommend CC Apex. This wheel features a premium polyurethane tread bonded to a durable aluminum core, delivering outstanding ergonomics, floor protection, and noise reduction. CC Apex is designed to handle heavy loads, navigate debris, and maintain smooth movement in both manual and towline applications.

What Makes CC Apex Stands Out

- 87 Shore A durometer for quiet operation, floor grip, and easier cart movement

- High rebound resilience to roll over debris and floor imperfections without slowing down

- Rounded donut tread for shock absorption, maneuverability, and grip

- Precision ball bearings for consistent, smooth rolling in tough environments

Shop CC Apex Casters

6" CC Apex Kingpinless Swivel Caster

SKU: CC-2110-600200-40-T1

ALT-SKU: CCAPEX-6S-KP

-

- Overall Height

- 7-1/2"

- Wt. Capacity

- 1,000 lbs.

- Wheel Width

- 2"

- Wheel Diameter

- 6"

6" CC Apex set - 2 swivel/2 rigid

SKU: CC-10/1210-600200-40-T1-SET4

ALT-SKU: CCAPEX-6S/R-set-2s/2r

-

- Overall Height

- 7-1/2"

- Wt. Capacity

- 1,000 lbs.

- Wheel Width

- 2"

- Wheel Diameter

- 6"

6" CC Peak Maintenance-Free Swivel CC Apex Caster

SKU: CC-3110-600200-40-T1

ALT-SKU: CCAPEX-6S-EMF

-

- Overall Height

- 7-1/2"

- Wt. Capacity

- 1,000 lbs.

- Wheel Width

- 2"

- Wheel Diameter

- 6"

SKU: CC-1010-300125-40-T4

ALT-SKU: CCAPEX-325-R

-

- Overall Height

- 4-1/4"

- Wt. Capacity

- 400 lbs.

- Wheel Width

- 1-1/4"

- Wheel Diameter

- 3"

SKU: DC-7512-300125-40-T6

ALT-SKU: CCAPEX-325-G-S-TP2

-

- Overall Height

- 4-1/8"

- Wt. Capacity

- 400 lbs.

- Wheel Width

- 1-1/4"

- Wheel Diameter

- 3"

8" CC Apex Kingpinless Swivel Caster with Extended Swivel Lead and Built in Brake

SKU: CC-2210-800200-40-T1-BIB

ALT-SKU: CCAPEX-8S-KP-EXT-BIB

-

- Overall Height

- 9-1/2"

- Wt. Capacity

- 1,200 lbs.

- Wheel Width

- 2"

- Wheel Diameter

- 8"

6" CC Peak Maintenance-Free Swivel CC Apex Caster w/ Extended Swivel Lead

SKU: CC-3210-600200-40-T1

ALT-SKU: CCAPEX-6S-EMF-EXT

-

- Overall Height

- 7-1/2"

- Wt. Capacity

- 1,000 lbs.

- Wheel Width

- 2"

- Wheel Diameter

- 6"

6" CC Peak Maintenance-Free Swivel CC Apex Caster w/ Built-In Brake

SKU: CC-3210-600200-40-T1-BIB

ALT-SKU: CCAPEX-6S-EMF-BIB

-

- Overall Height

- 7-1/2"

- Wt. Capacity

- 1,000 lbs.

- Wheel Width

- 2"

- Wheel Diameter

- 6"

Additional Option: CC Dynamo for Ultra Heavy-Duty Performance

While CC Apex is ideal for most fabrication and staging applications where ergonomics, shock absorption, and noise reduction are priorities, some operations demand even greater load capacity.

For very heavy carts, high mostly static loads, or continuous towline movement, the CC Dynamo lines provide a heavy-duty polyurethane solution built for extreme weight.

CC Dynamo 95A™

This wheel features a 95 Shore A polyurethane tread bonded to a cast iron core. It delivers increased load capacity with reduced tread deflection under heavy weight, while still providing more floor protection than harder polyurethane options. CC Dynamo 95A™ is a strong choice for heavy fabrication fixtures and loaded staging carts where weight is high but floor preservation still matters.

CC Dynamo 70D™

For the most demanding heavy-duty environments, CC Dynamo 70D™ steps up to a 70 Shore D polyurethane tread on a cast iron core. This firmer tread is engineered for maximum weight handling and minimal compression under constant load. It offers performance characteristics closer to steel, making it ideal for extreme-duty applications where load capacity is the primary concern.

Both CC Dynamo options allow manufacturers to move away from steel wheels while maintaining exceptional weight capacity and reducing the floor damage, noise, and shock transfer associated with fully metal wheels.

Shop CC Dynamo

8" CC Dynamo 95A Heavy Duty Rigid Caster

SKU: CC-9295A-800300-40-TV

-

- Overall Height

- 10-1/2"

- Wt. Capacity

- 3,600 lbs.

- Wheel Width

- 3"

- Wheel Diameter

- 8"

8" CC Dynamo 95A Heavy Duty Forged Kingpin Swivel Caster

SKU: CC-9395A-800300-40-TV

-

- Overall Height

- 10-1/2"

- Wt. Capacity

- 3,600 lbs.

- Wheel Width

- 3"

- Wheel Diameter

- 8"

8" CC Dynamo 95A Heavy Duty Kingpinless Swivel Caster

SKU: CC-9495A-800300-40-TV

-

- Overall Height

- 10-1/2"

- Wt. Capacity

- 3,600 lbs.

- Wheel Width

- 3"

- Wheel Diameter

- 8"

6" CC Dynamo 95A Heavy Duty Kingpinless Swivel Caster

SKU: CC-6195A-600300-40-T2

-

- Overall Height

- 7-1/2"

- Wt. Capacity

- 2,500 lbs.

- Wheel Width

- 3"

- Wheel Diameter

- 6"

6" CC Dynamo 95A Heavy Duty Rigid Caster

SKU: CC-1095A-600300-40-T2

-

- Overall Height

- 7-1/2"

- Wt. Capacity

- 2,500 lbs.

- Wheel Width

- 3"

- Wheel Diameter

- 6"

10" CC Dynamo 95A Heavy Duty Kingpinless Swivel Caster

SKU: CC-9495A-010300-40-TV

-

- Overall Height

- 12-1/2"

- Wt. Capacity

- 5,000 lbs.

- Wheel Width

- 3"

- Wheel Diameter

- 10"

8" CC Dynamo 70D Heavy Duty Kingpinless Swivel Caster

SKU: CC-9470D-800300-40-TV

-

- Overall Height

- 10-1/2"

- Wt. Capacity

- 3,600 lbs.

- Wheel Width

- 3"

- Wheel Diameter

- 8"

8" CC Dynamo 70D Heavy Duty Forged Kingpin Swivel Caster

SKU: CC-9370D-800300-40-TV

-

- Overall Height

- 10-1/2"

- Wt. Capacity

- 3,600 lbs.

- Wheel Width

- 3"

- Wheel Diameter

- 8"

8" CC Dynamo 70D Heavy Duty Rigid Caster

SKU: CC-9270D-800300-40-TV

-

- Overall Height

- 10-1/2"

- Wt. Capacity

- 3,600 lbs.

- Wheel Width

- 3"

- Wheel Diameter

- 8"

6" CC Dynamo 70D Heavy Duty Kingpinless Swivel Caster

SKU: CC-6170D-600300-40-T2

-

- Overall Height

- 7-1/2"

- Wt. Capacity

- 2,500 lbs.

- Wheel Width

- 3"

- Wheel Diameter

- 6"

6" CC Dynamo 70D Heavy Duty Rigid Caster

SKU: CC-1070D-600300-40-T2

-

- Overall Height

- 7-1/2"

- Wt. Capacity

- 2,500 lbs.

- Wheel Width

- 3"

- Wheel Diameter

- 6"

10" CC Dynamo 70D Heavy Duty Kingpinless Swivel Caster

SKU: CC-9470D-010300-40-TV

-

- Overall Height

- 12-1/2"

- Wt. Capacity

- 5,000 lbs.

- Wheel Width

- 3"

- Wheel Diameter

- 10"

The Bottom Line

Steel wheels may appear to be the toughest option, but in most fabrication and staging environments they cause unnecessary floor damage, add to noise levels, increase push/pull force, and transmit harmful shocks to both materials and workers. Polyurethane wheels match the strength of steel while offering safer, quieter, and more floor-friendly performance.

With a free Caster Needs Evaluation, our Caster Nerds will assess your equipment, load requirements, and conditions like floor type, debris, or washdowns, then recommend caster and wheel options that fit your operation. The right setup can help you cut downtime, protect your floors, and lower your total cost of ownership.