How to Choose the Best Casters for Heavy-Duty Equipment

How to Choose the Best Casters for Heavy-Duty Equipment

Choosing the right casters for heavy-duty equipment can make all the difference in terms of safety, efficiency, and cost. Whether you’re moving heavy machinery, industrial carts, storage containers, or other large equipment, understanding the key factors involved in caster selection will ensure smooth operation and prolonged equipment life. This guide will walk you through everything you need to know.

What Are Heavy-Duty Casters

Heavy-duty casters are designed to handle substantial weights, typically ranging from 1,000 to over 2,000 pounds per caster. Unlike standard casters, they are built with reinforced materials like high-quality polyurethane or steel and feature larger wheels to manage heavy loads without compromising on mobility. You’ll often find them in industries such as manufacturing, automotive, and material handling, where heavy equipment, machinery, or components require transportation across facilities. Heavy-duty casters are often designed in a dual-wheel style, with two wheels mounted side by side within the same frame. This setup distributes weight more evenly, increasing load capacity and stability.

5 Factors for Choosing Heavy-Duty Casters

When selecting casters for your heavy equipment, it’s crucial to consider specific factors to ensure you get the best performance:

1. Load Capacity

One of the first things to determine is how much weight the caster needs to support. Make sure to calculate the total weight of the equipment, plus any additional load it will carry. To determine the load capacity that each caster must handle, divide the total load by the number of casters being used, minus one. Always choose casters with a load capacity higher than your calculated requirement to avoid overloading and potential failures.

2. Wheel Tread Material

The material of the caster wheels affects their durability, traction, and how they interact with different surfaces. Popular materials include:

- Polyurethane: Ideal for smooth surfaces; resistant to chemicals.

- Steel: Suitable for extreme weights and rough indoor terrain.

- Rubber: Provides cushioning but may not be suited for extremely heavy loads.

Choose a material that aligns with your facility's environment to ensure longevity and optimal performance.

3. Wheel Size

Wheel size directly impacts mobility. Larger wheels can roll over obstacles more easily and provide a smoother ride. However, they also require more space. Consider the environment and any potential obstructions when deciding on the appropriate wheel size.

4. Environmental Conditions

If your equipment operates in extreme conditions (e.g., high temperatures, exposure to chemicals, or moisture), it’s important to select casters designed to withstand those elements. Casters with corrosion-resistant finishes and high-heat materials can handle environments that would quickly wear down commodity casters.

5. Maneuverability & Ergonomics

Push/pull resistance directly affects operator safety and productivity. Choosing swivel casters can make it easier to navigate tight spaces, while pairing them with rigid ones can provide added control. Considering the ergonomic capabilities of your casters will ensure that you are reducing strain for your employees and improving their overall efficiency.

Types of Heavy-Duty Casters for Various Equipment Needs

Not all casters are created equal, and the type you need will depend on your equipment and how you intend to use it. Here are some popular types of heavy-duty casters:

Swivel Casters

Swivel casters can rotate 360 degrees, making them ideal for navigating confined spaces. Their flexibility makes them perfect for carts, dollies, and equipment that frequently needs to change direction.

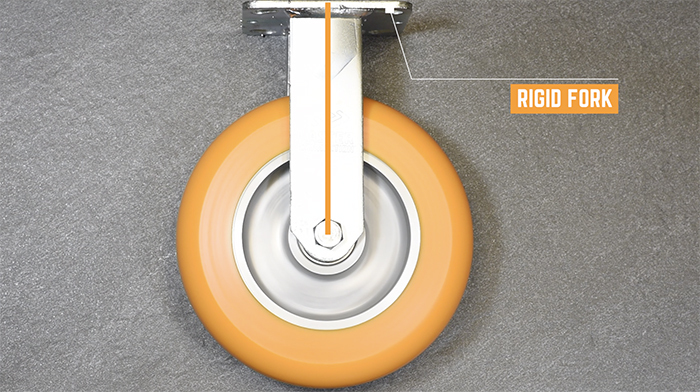

Rigid Casters

Rigid casters are fixed in a straight-line direction, providing greater stability for transporting heavy loads over longer distances. These casters are often used in combination with swivel casters to enable straight-line travel while maintaining some maneuverability.

Locking Casters

Locking casters come equipped with built-in brakes that prevent the wheels from rolling or swiveling. They are ideal for equipment that needs to remain stationary when not in use, such as workbenches or carts on inclined surfaces.

How to Select Casters for Different Work Environments

Every work environment has unique demands, and choosing the right caster depends on understanding these specific needs. For example:

Manufacturing Plants

Opt for high-durability polyurethane or steel casters that can handle heavy loads and rough floors.

Cleanrooms & Medical Facilities

Choose casters with non-marking, chemical-resistant wheels.

Shop Our Best-Selling Heavy-Duty Equipment Casters:

SKU: CC-1210-600200-40-T1

ALT-SKU: CCAPEX-6S

-

- Overall Height

- 7-1/2"

- Wt. Capacity

- 1,000 lbs.

- Wheel Width

- 2"

- Wheel Diameter

- 6"

6" CC Apex Kingpinless Swivel Caster

SKU: CC-2110-600200-40-T1

ALT-SKU: CCAPEX-6S-KP

-

- Overall Height

- 7-1/2"

- Wt. Capacity

- 1,000 lbs.

- Wheel Width

- 2"

- Wheel Diameter

- 6"

6" CC Peak Maintenance-Free Swivel CC Apex Caster

SKU: CC-3110-600200-40-T1

ALT-SKU: CCAPEX-6S-EMF

-

- Overall Height

- 7-1/2"

- Wt. Capacity

- 1,000 lbs.

- Wheel Width

- 2"

- Wheel Diameter

- 6"

SKU: CC-1210-800200-40-T1

ALT-SKU: CCAPEX-8S

-

- Overall Height

- 9-1/2"

- Wt. Capacity

- 1,200 lbs.

- Wheel Width

- 2"

- Wheel Diameter

- 8"

8" CC Apex Kingpinless Swivel Caster

SKU: CC-2110-800200-40-T1

ALT-SKU: CCAPEX-8S-KP

-

- Overall Height

- 9-1/2"

- Wt. Capacity

- 1,200 lbs.

- Wheel Width

- 2"

- Wheel Diameter

- 8"

8" CC Peak Maintenance-Free Swivel CC Apex Caster w/ Extended Swivel Lead

SKU: CC-3210-800200-40-T1

ALT-SKU: CCAPEX-8S-EMF-EXT

-

- Overall Height

- 9-1/2"

- Wt. Capacity

- 1,200 lbs.

- Wheel Width

- 2"

- Wheel Diameter

- 8"

8" CC Nexus Kingpinless Swivel Caster - 4" X 4-1/2" top plate

SKU: CC-2115-800200-40-T1

-

- Overall Height

- 9-1/2"

- Wt. Capacity

- 1,750 lbs.

- Wheel Width

- 2"

- Wheel Diameter

- 8"

8" CC Nexus Kingpinless Swivel Caster with Extended Swivel Lead - 4" X 4-1/2" top plate

SKU: CC-2215-800200-40-T1

-

- Overall Height

- 9-1/2"

- Wt. Capacity

- 1,750 lbs.

- Wheel Width

- 2"

- Wheel Diameter

- 8"

8" CC Nexus Maintenance-Free Outrigger-Style Swivel Caster - 4" X 4-1/2" top plate

SKU: CC-3115-800200-40-T1-RG

-

- Overall Height

- 9-1/2"

- Wt. Capacity

- 3,500 lbs.

- Wheel Width

- 2"

- Wheel Diameter

- 8"

SKU: CC-3215-800200-40-T1-RG

-

- Overall Height

- 9-1/2"

- Wt. Capacity

- 3,500 lbs.

- Wheel Width

- 2"

- Wheel Diameter

- 8"

SKU: CC-3315-800200-40-T1-RG

-

- Overall Height

- 10-1/8"

- Wt. Capacity

- 3,500 lbs.

- Wheel Width

- 2"

- Wheel Diameter

- 8"

8" CC Nexus Outrigger-Style Rigid Caster - 4" X 4-1/2" top plate

SKU: CC-1015-800200-40-T1-RG

-

- Overall Height

- 9-1/2"

- Wt. Capacity

- 1,250 lbs.

- Wheel Width

- 2"

- Wheel Diameter

- 8"

Choosing the Right Casters for Heavy-Duty Equipment

Selecting the right casters for heavy-duty equipment doesn’t have to be complicated. By considering factors such as load capacity, wheel material, and the specific demands of your environment, you can ensure that your equipment moves safely and efficiently. Investing in the right casters will save you from costly repairs, improve productivity, and enhance safety across your operations.

Need A Heavy-Duty Caster Solution for Your Facility?

Try CC CHAT (Caster Health Assessment Tour), our free consultative service that provides you with actionable solutions for improving your mobility efforts.