Case Study: Improving Ergonomics, Durability, and Cart Mobility in Automotive Machining

In automotive machining environments, material handling equipment is routinely exposed to harsh conditions—including metal chips, machining coolant, and continuous use. When casters are not properly matched to these conditions, facilities can experience increased operator strain, reduced productivity, and premature equipment failure. In this case study, a large automotive casting operation partnered with Caster Connection to address persistent mobility and ergonomic challenges associated with chip bins used throughout its machining lines. By evaluating real-world operating conditions and selecting a more durable caster solution, the facility achieved a noticeable improvement in cart maneuverability, operator comfort, and long-term performance.

The Challenge

The facility was experiencing ongoing ergonomic and durability issues with chip bins used in daily machining operations.

The bins were outfitted with 3” × 1-1/2” nylon wheels with roller bearings, mounted on kingpin-style swivel and rigid casters. These casters operated in an environment characterized by:

-

Continuous exposure to machining coolant

-

Frequent starts, stops, and directional changes

Over time, metal chips embedded into the wheel tread while coolant infiltrated the wheel bearings. As contamination increased, rolling resistance worsened, making chip bins increasingly difficult to move. Operators often needed a forceful two-hand push to reposition carts—raising concerns around ergonomics, fatigue, and the risk of injury, while also slowing routine material handling tasks.

The Solution

Caster Connection worked closely with the facility’s engineering team to fully understand the application, including load requirements, duty cycle, and the chemical composition of the machining coolant. This step ensured that any proposed wheel material would remain compatible and perform reliably over time.

Based on these findings, Caster Connection recommended upgrading the existing caster configuration to:

-

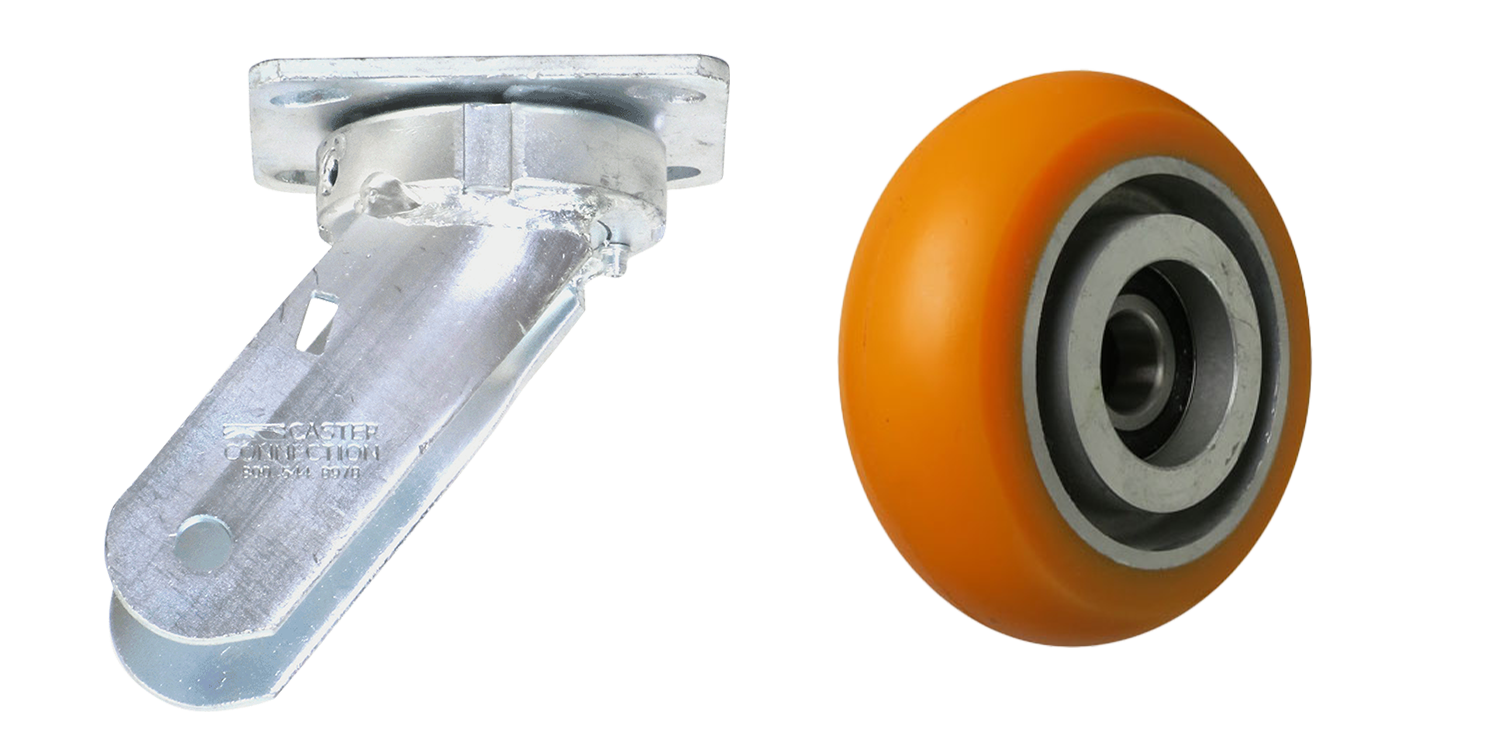

Mounted on extended lead CC Alpha rigs

-

A combination of swivel and rigid configurations to maintain control and maneuverability

While the new casters introduced a modest increase in overall load height, the change did not negatively affect operations and was approved for an extended in-plant trial.

The Results

The facility conducted a five-month trial to evaluate both immediate and long-term performance under real production conditions. Although no force gauge measurements were recorded, the improvement in mobility was clear and consistently reported by operators.

Key results included:

- Chip bins that previously required a difficult two-hand push could now be easily guided with one hand

- Significantly reduced rolling resistance in coolant-exposed areas

- No metal chip buildup on the wheel tread

- No bearing failures or performance degradation during the trial period

- Strong operator acceptance based on daily use and “feel”

Operators described the improvement as immediately noticeable, citing easier starts, smoother movement, and better control when navigating tight machining areas.

Implementation & Impact

Following the successful trial, the facility placed a production order and expanded the use of the upgraded caster solution across additional chip carts. The new casters were also specified for carts supporting a new machining line, where they were later highlighted during internal and executive-level facility tours.

Caster Connection continues to support the facility with application expertise as it expands and modernizes its material handling systems.

Need a Custom Caster Solution for Your Facility?

Try Caster Needs Eval, our free consultative service that delivers an onsite mobility evaluation and custom plan to help improve safety, efficiency, and total cost for your operation.