How Ergonomic Casters Improve Safety and Cut Costs

In material handling environments, the focus is often on speed, output, and productivity. But one factor directly affects all three: ergonomics. Poor ergonomics can lead to workplace injuries, slower workflows, and long-term costs that pile up quickly.

At Caster Connection, we believe ergonomic design isn't optional. It's essential. From reducing injury risk to improving equipment performance, ergonomic casters help businesses create safer workplaces and save money in the process. In this blog, we’ll explore how smart caster design improves comfort, movement, and the bottom line.

The Cost of Poor Ergonomics

Injuries from pushing, pulling, and maneuvering heavy carts are among the most common in warehouses and manufacturing facilities. The financial impact includes:

-

Increased workers' compensation claims

-

Lost productivity

-

Higher insurance premiums

-

Employee turnover due to strain or discomfort

According to OSHA and the CDC, musculoskeletal disorders make up a large share of work-related injuries. Many of these are preventable with better equipment design, including ergonomically optimized casters.

How Ergonomic Casters Make a Difference

Ergonomics in caster design isn’t about just one feature. It’s the result of multiple factors working together to reduce strain and improve performance. From rolling resistance to tread material, each element plays a role in how safely and efficiently workers can move loads. Here’s how smart caster design directly supports better ergonomics on the floor.

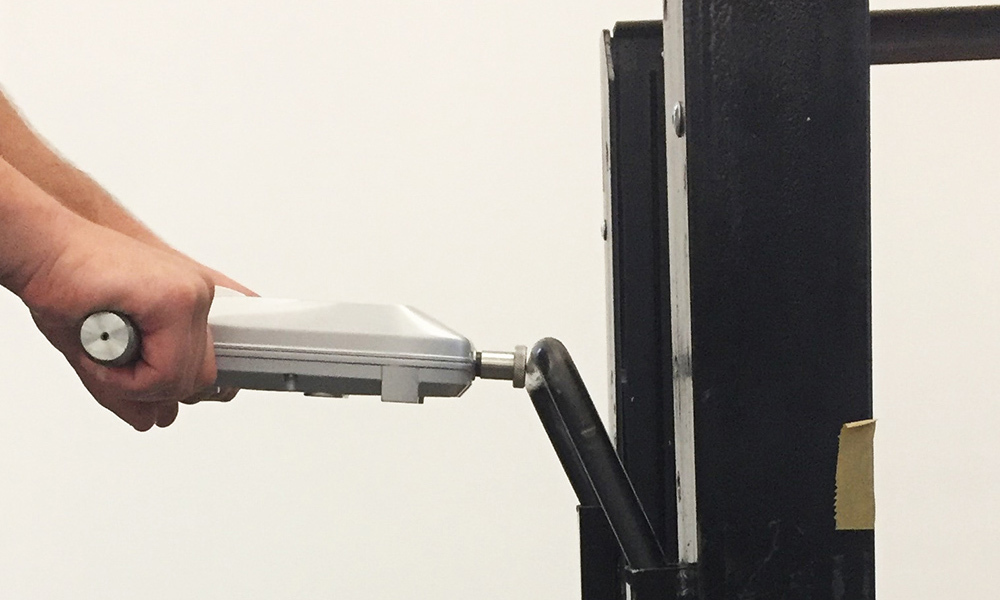

Lower Push/Pull Force

Casters with low rolling resistance significantly reduce the effort required to move loads. This helps limit shoulder and back strain, lowers the risk of repetitive stress injuries, and allows employees to handle heavier loads more safely.

Better Swivel and Tracking

If a caster doesn’t swivel properly, every turn becomes a fight. High-quality swivel sections and precision bearings reduce resistance, making it easier for workers to control movement and maintain direction with less physical effort.

Floor-Friendly Tread Materials

Ergonomic casters also protect workers and facility floors through shock absorption and smoother motion. Polyurethane treads, for example, glide over concrete, reduce noise, and lessen the impact of vibration.

Proper Load Matching and Configuration

Overloading or under-specifying casters can have ergonomic consequences. Too much resistance makes movement difficult, while too little durability leads to early failure. Ergonomics depends on selecting the right caster for both the load and the working environment.

Ergonomics Improves Efficiency, Safety, and Savings

When workers struggle to move carts, your entire operation slows down. Poor ergonomics creates safety risks, increases fatigue, and drives up long-term costs. A well-designed caster setup removes those barriers and helps your team work smarter.

Fewer Injuries

Reducing the physical effort required to push and pull carts lowers the risk of musculoskeletal injuries. That means fewer workers' comp claims and less downtime due to strain or fatigue.

Lower Turnover

Employees are more likely to stay in roles where their tools and equipment support their physical well-being. Better ergonomics leads to better retention and fewer retraining costs.

Smoother Material Movement

Casters with proper swivel action and low rolling resistance allow for faster, more controlled movement. This translates into fewer workflow disruptions and more consistent performance across shifts.

Less Product and Equipment Damage

When carts are harder to control, it increases the chances of collisions, dropped loads, or floor damage. Ergonomic casters make movement more predictable, which protects both your products and your facility.

Improving caster ergonomics isn't a small tweak. It's a practical step that improves performance, protects your team, and saves money across the operation.

Shop Ergonomic Casters

8" CC Nexus Kingpinless Swivel Caster with Extended Swivel Lead - 4" X 4-1/2" top plate

SKU: CC-2215-800200-40-T1

-

- Overall Height

- 9-1/2"

- Wt. Capacity

- 1,750 lbs.

- Wheel Width

- 2"

- Wheel Diameter

- 8"

8" CC Nexus Kingpinless Swivel Caster with Built-In Brake - 4" X 4-1/2" top plate

SKU: CC-2115-800200-40-T1-BIB

-

- Overall Height

- 9-1/2"

- Wt. Capacity

- 1,750 lbs.

- Wheel Width

- 2"

- Wheel Diameter

- 8"

8" CC Axis Rigid CC Apex Caster

SKU: CC-7010-800200-40-T2

ALT-SKU: CCAPEX-8R-AXIS

-

- Overall Height

- 11-1/2"

- Wt. Capacity

- 1,200 lbs.

- Wheel Width

- 2"

- Wheel Diameter

- 8"

8" CC Axis Rigid CC Stout HD Caster

SKU: CC-7051-800200-40-T2

-

- Overall Height

- 11-1/2"

- Wt. Capacity

- 1,750 lbs.

- Wheel Width

- 2"

- Wheel Diameter

- 8"

8" CC Peak Maintenance-Free Swivel CC Apex Caster w/ Extended Swivel Lead

SKU: CC-3210-800200-40-T1

ALT-SKU: CCAPEX-8S-EMF-EXT

-

- Overall Height

- 9-1/2"

- Wt. Capacity

- 1,200 lbs.

- Wheel Width

- 2"

- Wheel Diameter

- 8"

6" CC Peak Maintenance-Free Swivel CC Stout HD Caster

SKU: CCSTOUT-6S-EMF

ALT-SKU: CC-3150-600200-40-T1

-

- Overall Height

- 7-1/2"

- Wt. Capacity

- 1,200 lbs.

- Wheel Width

- 2"

- Wheel Diameter

- 6"

Real-World Ergonomic Savings: Safer Workflow, Better Results

A regional manufacturer was dealing with a steady rise in ergonomic complaints from team members pushing heavy work-in-progress carts. After consulting with Caster Connection, the facility upgraded to ergonomic polyurethane casters with precision bearings.

The results were immediate:

-

Ergonomic incidents dropped by 60 percent

-

Average cart movement time improved by 20 percent

-

Employee satisfaction and workflow consistency increased across departments

What started as a caster upgrade turned into a broader improvement in productivity and workplace safety.

Invest in the People Who Power Your Productivity

Ergonomic improvements don’t just protect your workforce—they directly support efficiency, safety, and your bottom line. The right caster design can reduce fatigue, improve material flow, and eliminate hidden costs tied to injuries and slow production.

If you're ready to make your operation safer and more efficient, we can help. Our team will assess your current setup and recommend ergonomic caster solutions that make a measurable difference. You can start by booking a Caster Needs Evaluation, exploring ergonomic caster options, or talking to an expert about your specific challenges.