How to Prevent Metal Debris from Damaging Your Casters

How to Prevent Metal Debris from Damaging Your Casters

In industrial environments, metal debris is a common problem that can have a serious impact on the performance of caster wheels. From metal shavings and welding slag to stray screws, this type of debris can lead to increased friction, wheel damage, floor deterioration, and even safety hazards if not properly managed. Understanding how metal debris affects casters and learning how to prevent related issues can help you maintain smooth and efficient operations.

In this blog, we'll explore the effects of metal debris on caster wheels, common sources of debris, and practical steps to keep your casters running smoothly.

How Metal Debris Affects Caster Wheel Performance

Metal debris is a common issue in many industrial environments, often generated from manufacturing processes, equipment wear, and even routine maintenance activities. For instance, metal shavings can accumulate during machining operations, while loose screws or nuts may fall from machinery. Additionally, metal fabrication shops can see an influx of small metal fragments from cutting, welding, and other processes. When this debris finds its way onto the floors of warehouses, factories, or workshops, it poses a significant risk to caster wheels.

The presence of metal debris can cause multiple problems for caster wheels, including:

- Friction and Rolling Resistance: When debris gets caught in the wheels, it increases friction and rolling resistance, making it harder to move carts, racks, and equipment. This can lead to higher energy consumption for AGVs and increased strain on employees, ultimately affecting productivity. This can also increase risk of overexertion, due to higher push/pull efforts. Consequently, this can lead to work-related injuries and/or costly downtime.

- Wheel Damage: Sharp metal fragments can cut, puncture, or scrape caster wheels, especially those made from softer materials. This damage not only shortens the lifespan of the wheels but can also lead to costly replacements and increased downtime.

- Bearing Issues: Debris can enter the bearings and cause jamming or restricted movement. When bearings are blocked, the wheel’s ability to turn is compromised, which can affect maneuverability and lead to caster failure. This can create safety hazards and disrupt workflow.

- Compromised Load Capacity: Damaged wheels may not be able to support their intended load capacity, increasing the risk of accidents or equipment failures. A failure to address these issues can have serious implications for both safety and efficiency.

Common Sources of Metal Debris in Industrial Settings

Understanding where metal debris comes from can help you anticipate and address problems before they arise. Common sources include:

Metal Shavings & Cuttings

Generated during machining, drilling, or cutting processes, these tiny fragments can easily become lodged in caster wheels.

Loose Screws, Nuts, & Bolts

Regular maintenance activities or equipment assembly can lead to small metal parts falling onto the floor.

Welding Residue

Leftover welding slag or metal bits can get stuck in the wheels, causing rolling issues.

Scrap Pieces

In environments like automotive manufacturing or metal fabrication shops, small scrap pieces often end up on the floor, creating a risk for casters.

Best Practices for Preventing Metal Debris Issues

Preventive measures can go a long way in ensuring that your caster wheels stay in good condition. Here are some best practices:

- Routine Maintenance: Regularly inspect casters for signs of damage or debris build-up. This can help catch potential problems early before they cause serious issues.

- Proper Cleaning: Clean wheels frequently to remove any stuck debris. Use tools like compressed air or brushes to clear out hard-to-reach areas.

- Use of Guards and Deflectors: Consider installing wheel guards or sweeper attachments to help deflect debris away from casters. These tools can keep metal fragments from pressing into the wheel tread and entering the bearings.

- Regular Inspections: Develop a checklist for inspecting caster wheels. This should include checking for debris, signs of wear, and verifying that all components are in good working order.

Selecting the Right Casters for Debris-Prone Environments

Choosing the right caster wheel is essential in environments where metal debris is common. The right casters can help reduce wear and tear, enhance maneuverability, and improve safety. In settings such as manufacturing plants and construction sites, metal shavings, loose screws, and other fragments can easily accumulate, leading to potential damage.

Selecting casters designed to withstand these challenges is crucial. The following factors will help guide your decision, ensuring you choose casters that repel debris, protect sensitive flooring, and maintain optimal performance.

Debris-Resistant Materials Like Polyurethane

High-quality polyurethane casters, like CC Apex and CC Apex HD, are an excellent choice for industrial settings because of their ability to repel, rather than retain, debris. Unlike softer rubber wheels, which can embed sharp fragments, polyurethane’s smooth, non-porous surface prevents metal particles from sticking. This reduces the risk of damage and keeps the wheels in prime condition. Additionally, polyurethane casters are more resistant to chemicals and moisture, making them durable in various conditions.

Protection for Sensitive Floors

Another key benefit of polyurethane casters is their ability to protect sensitive floors. Unlike harder materials, such as metal or steel casters, polyurethane wheels are softer and gentler on surfaces. This makes them ideal for environments where flooring needs to be preserved, such as warehouses with epoxy-coated floors or facilities with polished concrete. They offer a balance of durability and floor protection, reducing the likelihood of scratches, scuffs, and other damage caused by hard debris.

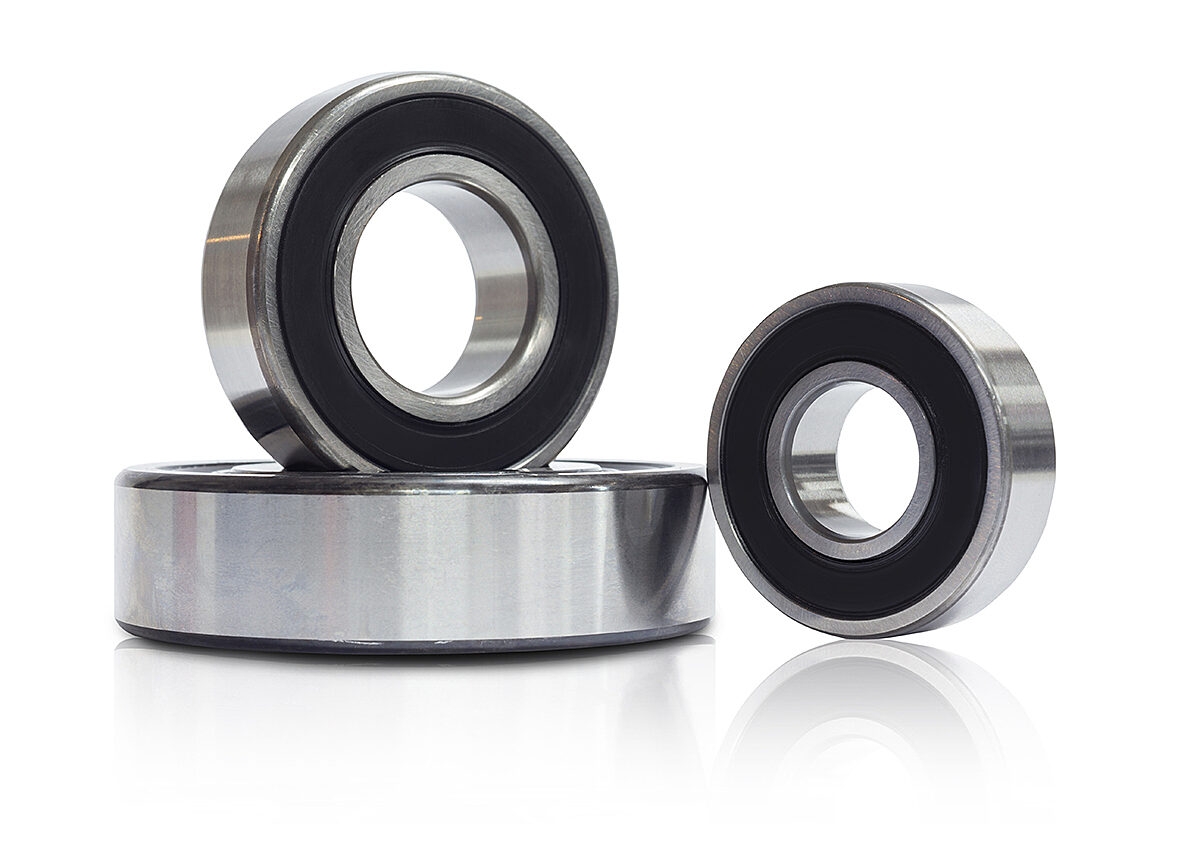

Sealed Bearings for Extra Protection

To enhance the performance of caster wheels in debris-prone environments, consider using casters equipped with sealed precision ball bearings, like our line of maintenance-free casters. By sealing both ends of the bearings, we have designed our maintenance-free casters to prevent metal fragments, dust, and unwanted moisture from entering the internal mechanisms. By keeping debris out, sealed bearings reduce the risk of jamming, ensuring reliable performance over time.

Additionally, our maintenance-free casters with sealed bearings require less maintenance than other casters, since they are self-lubricating. By investing in casters with sealed bearings, you can prolong the lifespan of your wheels, making them a smart choice for demanding industrial applications.

CC Apex: The Number 1 Choice for Metal Fabrication Shops

- Signature high-quality polyurethane formula repels debris like a pro

- Low maintenance and long-lasting

- Higher load capacity than other polyurethane casters

- Low decibel output helps reduce noise

Shop CC Apex

SKU: CC-1210-600200-40-T1

ALT-SKU: CCAPEX-6S

-

- Overall Height

- 7-1/2"

- Wt. Capacity

- 1,000 lbs.

- Wheel Width

- 2"

- Wheel Diameter

- 6"

SKU: CC-1010-600200-40-T1

ALT-SKU: CCAPEX-6R

-

- Overall Height

- 7-1/2"

- Wt. Capacity

- 1,000 lbs.

- Wheel Width

- 2"

- Wheel Diameter

- 6"

6" CC Apex Kingpinless Swivel Caster

SKU: CC-2110-600200-40-T1

ALT-SKU: CCAPEX-6S-KP

-

- Overall Height

- 7-1/2"

- Wt. Capacity

- 1,000 lbs.

- Wheel Width

- 2"

- Wheel Diameter

- 6"

6" CC Apex set - 2 swivel/2 rigid

SKU: CC-10/1210-600200-40-T1-SET4

ALT-SKU: CCAPEX-6S/R-set-2s/2r

-

- Overall Height

- 7-1/2"

- Wt. Capacity

- 1,000 lbs.

- Wheel Width

- 2"

- Wheel Diameter

- 6"

6" CC Peak Maintenance-Free Swivel CC Apex Caster

SKU: CC-3110-600200-40-T1

ALT-SKU: CCAPEX-6S-EMF

-

- Overall Height

- 7-1/2"

- Wt. Capacity

- 1,000 lbs.

- Wheel Width

- 2"

- Wheel Diameter

- 6"

6" CC Peak Maintenance-Free Swivel CC Apex Caster w/ Extended Swivel Lead

SKU: CC-3210-600200-40-T1

ALT-SKU: CCAPEX-6S-EMF-EXT

-

- Overall Height

- 7-1/2"

- Wt. Capacity

- 1,000 lbs.

- Wheel Width

- 2"

- Wheel Diameter

- 6"

8" X 3" CC APEX HD SWIVEL CASTER 10-1/8 OVERALL HEIGHT

SKU: DC-5320-800300-40-T2

ALT-SKU: CCAPEXHD-830-S

-

- Overall Height

- 10-1/8"

- Wt. Capacity

- 2,700 lbs.

- Wheel Width

- 3"

- Wheel Diameter

- 8"

8" X 3" CC APEX HD KINGPINLESS SWIVEL CASTER 10-1/8 OVERALL HEIGHT

SKU: CC-6120-800300-40-T2

ALT-SKU: CCAPEXHD-830-S-KP

-

- Overall Height

- 10-1/8"

- Wt. Capacity

- 2,700 lbs.

- Wheel Width

- 3"

- Wheel Diameter

- 8"

8" X 3" CC APEX HD DUAL-WHEEL SWIVEL CASTER 10-1/2 OVERALL HEIGHT

SKU: DC-D220-800300-40-T7

ALT-SKU: CCAPEXHD-830-SKPD-TP2-OH2

-

- Overall Height

- 10-1/2"

- Wt. Capacity

- 5,400 lbs.

- Wheel Width

- 3"

- Wheel Diameter

- 8"

Safeguard Your Facility's Efficiency & Longevity with the Best Casters

Metal debris is a significant concern for anyone operating in industrial settings, but it doesn’t have to derail your workflow. By understanding how metal debris impacts caster performance, taking preventive measures, and selecting the right type of wheels, you can reduce downtime, lower maintenance costs, and improve workplace safety.

For more information on debris-resistant casters and to find solutions tailored to your needs, contact Caster Connection today.

Need a Custom Caster Solution for Your Facility?

Try CC CHAT (Caster Health Assessment Tour), our free consultative service that provides you with actionable solutions for improving your mobility efforts.