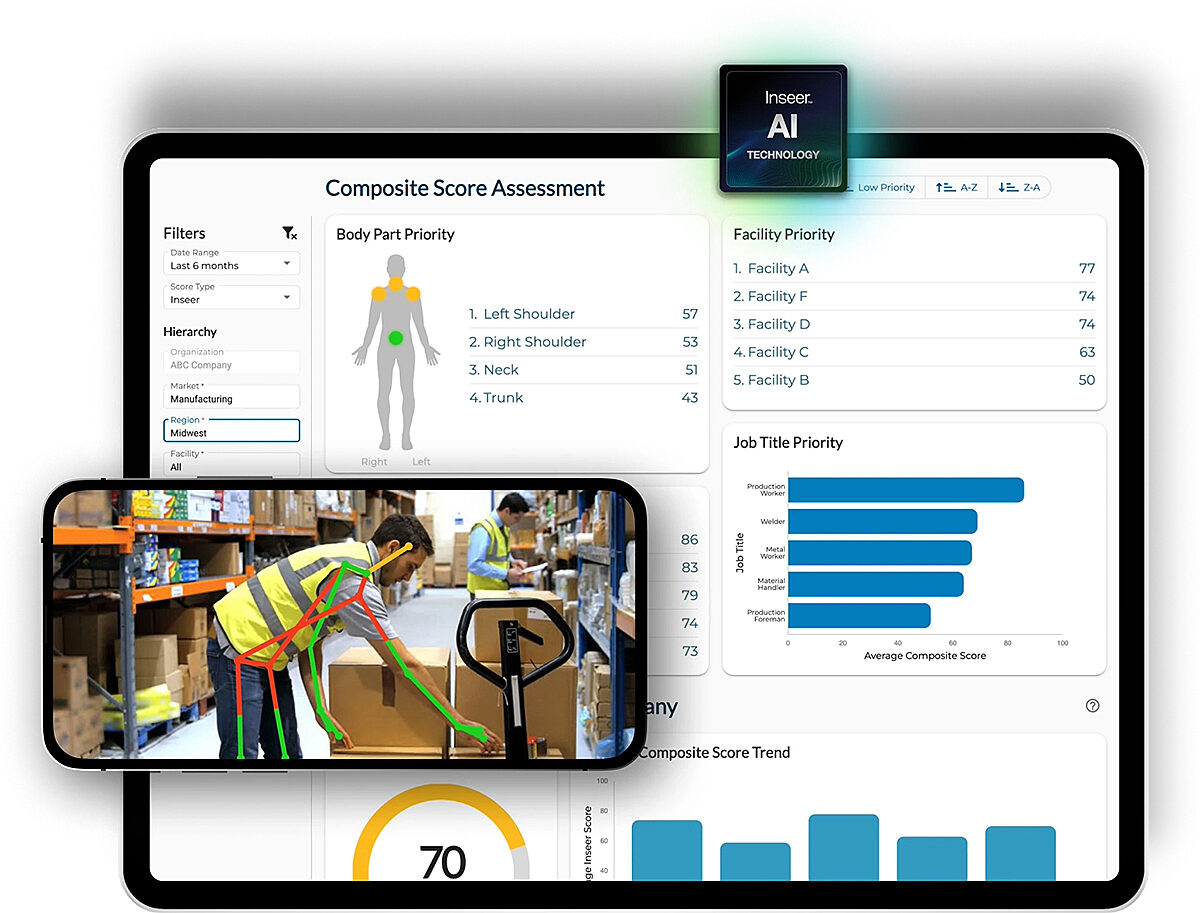

Turning Motion Into Math: How Inseer is Revolutionizing Ergonomics - The Industrial Lens Podcast

On today’s plant floors, jobs like pushing heavy carts, lifting awkward parts, or working overhead can lead to costly muscle and joint injuries. Yet many safety teams still measure these tasks with clipboards and stopwatches. In this episode of The Industrial Lens, host Eric Hassen talks with Shane Larson, CEO of Inseer, about a better way: record a short video of a task, let advanced software calculate forces, angles, and posture risks automatically, and turn that data into clear solutions that make jobs safer and more efficient.

It’s a straightforward way to spot risks, measure them with real data, and move beyond the guesswork.

How Inseer Works

Inseer analyzes a short smartphone video and calculates joint angles, speeds, distances, and torque with lab-level accuracy. Instead of one-off manual measurements, every analysis runs on the same validated models, so results are consistent no matter who captures the footage.

- Human in the loop. A person records the task and reviews the results while the software analyzes the footage to estimate risk. Inseer isn’t a continuous surveillance system, and every automated step can be adjusted so experts stay in control.

- Grounded in validation. Inseer’s models are trained against motion capture ground truth. The team shares raw data and calculations so your specialists can check the numbers.

- Enterprise ready. Inseer is SOC 2 Type 2 compliant and can integrate with EHS platforms so data lives where leaders already work.

The result is a faster path from “we think there is a problem” to “here is the measurement, here is the fix, here is the before and after.”