Selecting the Right Casters for Cannabis Warehouse and Distribution

As the cannabis industry expands, warehousing and distribution operations are becoming more complex. What began in small storage rooms has grown into regional fulfillment hubs managing high-value, regulated inventory. Efficiency, safety, and speed are now critical—and the ability to move product smoothly and securely plays a central role in operational success.

At the core of that mobility are casters. Choosing the right caster setup for carts, racks, and mobile pallet systems is essential for protecting your inventory, keeping workers safe, and avoiding costly downtime.

The Mobility Demands of Cannabis Warehousing

Cannabis facilities face unique challenges that set them apart from traditional warehouses. Regulatory compliance, limited space, and product sensitivity require equipment that performs reliably under pressure.

Key mobility challenges include:

-

Transporting high-value, fragile goods like packaged flower and oils

-

Navigating narrow aisles with limited room for turns

-

Frequent cross-floor movement between polished concrete, epoxy, or rubber mats

-

Supporting heavy, shifting loads during picking, staging, or order fulfillment

Casters in this environment face constant stress, sharp directional changes, and extended duty cycles. If the wrong casters are used, they quickly become a source of slowdowns, floor damage, or even workplace injuries.

Load Capacity is More Critical Than You Think

In cannabis distribution, carts and dollies carry more than just packaging materials. They often support concentrated weight from bulk containers, branded goods, oils, edibles, and regulatory equipment. One of the biggest caster selection mistakes is underestimating load demands.

When evaluating load capacity, consider:

-

The maximum anticipated load each cart or dolly will carry

-

The number of casters sharing that load (usually four or six)

-

An added buffer for dynamic forces like cornering or uneven flooring

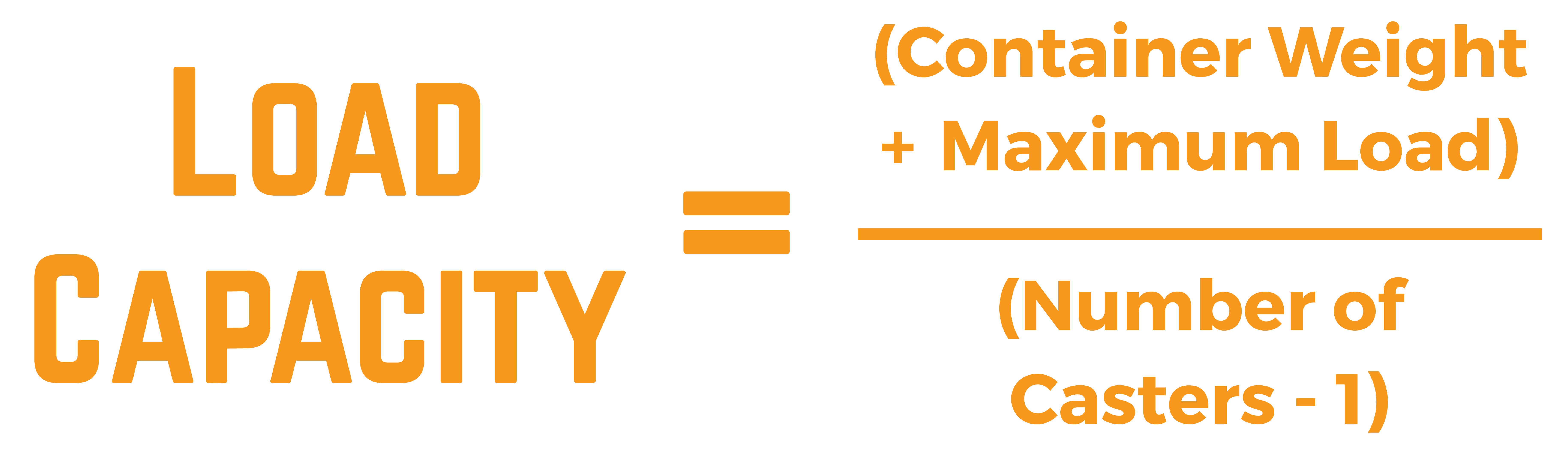

Tip: Never divide the total weight evenly across all casters. Assume that only three casters may carry the full load at times due to uneven distribution. Choosing a heavier-duty caster ensures smoother rolling, reduced strain on workers, and longer service life.

Performance Expectations in a Cannabis Warehouse

Cannabis warehouses are fast-paced, multi-shift environments where efficiency and reliability go hand in hand. Mobile equipment often performs dozens or even hundreds of movements per day across a variety of tasks.

Casters in these settings must:

-

Handle frequent stops, starts, and turns without binding

-

Maintain smooth rolling on different floor types

-

Stay stable when stationary for picking or loading tasks

-

Withstand heavy use without constant maintenance

To meet these demands, quality casters should offer:

-

Precision sealed ball bearings for consistent, low-resistance movement

-

Directional swivel control for navigating tight aisleways

-

Durable, shock-absorbing wheels that won’t degrade quickly

-

Reliable brakes that keep carts locked in place when needed

What Makes a Caster "High-Performance" in Cannabis Distribution?

Not all casters are created equal. For cannabis warehousing, you need a combination of strength, control, and ergonomic benefits to protect both product and personnel. Here are some recommended caster features.

Wheel Materials

- Polyurethane: Non-marking and ideal for concrete or epoxy flooring. These wheels are quiet, durable, and provide good load capacity without damaging surfaces.

- Thermoplastic rubber: Offers quieter rolling and added shock absorption for fragile products or uneven surfaces.

- Forged steel: Best for extremely heavy loads or rough floors, though they tend to be noisier and can mark some surfaces.

Bearing Type

- Sealed precision bearings: Reduce push force and protect internal components from dust and debris.

-

Maintenance-free options: Ideal for facilities that cannot schedule routine caster servicing.

Rigs and Mounts

- Zinc-plated or stainless steel rigs: Provide corrosion resistance and are suitable for damp or sanitized environments.

-

Shock-absorbing rigs: Help protect fragile product when carts move across uneven surfaces or thresholds.

Each of these elements contributes to safer, smoother, and more durable caster performance. This level of reliability is especially important when time, safety, and compliance are all at stake.

Caster Connection's Solutions for Cannabis Warehouses and Distribution Centers

At Caster Connection, we help cannabis companies improve their warehouse mobility with solutions designed for demanding, regulated environments. From small batch facilities to multi-site distribution centers, we tailor our recommendations to fit your specific needs.

We commonly support:

-

Bulk storage carts and bins

-

Order picking carts and staging tables

-

Distribution racks and cage carts

-

Mobile shelving and pallet dollies

Our go-to caster solutions include:

-

Heavy-duty polyurethane wheels with sealed bearings for easy movement under heavy loads

-

Swivel and total-lock braking casters to improve safety and control

-

Toe guards and rig reinforcements for protection in high-impact areas

-

Custom caster configurations to retrofit existing carts or support new builds

Our team evaluates your warehouse layout, floor conditions, and load expectations to ensure every caster supports your throughput and safety goals.

Your Distribution Center Efficiency Depends on the Right Wheels

Cannabis warehousing is more than storage. It’s the engine that drives product movement from facility to dispensary. If your carts are hard to maneuver, unstable under load, or damaging your floors, you're not just dealing with inconvenience—you’re risking performance and profitability.

Don’t let outdated caster systems create bottlenecks in your operation. With the right caster setup, your team can move faster, safer, and smarter.

Need help upgrading your warehouse mobility? Connect with a Caster Connection expert today through a Caster Needs Evaluation and let’s keep your distribution moving forward.