Types of Plate-Mount Caster Rigs

We know that many people out there don’t even know what a caster is. It is indeed a horrible thought, but sadly, it’s a reality. So, when we start talking about parts of casters, we’re entering a bit more rarified air. Those who enter this airspace, however, will gain benefits that will save them and their company thousands upon thousands of dollars and help them avoid a whole host of serious problems. Now, even though we’ve already covered much of the wheel, the fork, lead, and brakes, we must not leave one part out. We’re talking about the raceway/swivel section, and by the time you’ve perused this article, you can consider yourself one of an elite group of caster masters.

The raceway is connected to the fork and top plate, which connects directly to the cart. Raceways are found only on swivel rigs, that is, rigs that can move in 360 degrees. Because of this, you might hear “swivel section” used for “raceway.” Rigid forks don’t have a raceway; they simply have a top plate. Swivel rigs have raceways, and this raceway allows the caster to swivel, hence swivel rigs.

To confuse things a bit more, an entire caster rig is usually referred to by its raceway. So, for example, a caster with a kingpin raceway is often called a “kingpin rig” or “kingpin caster.” This is similar to how cars are often called by their transmission type, for example, a “standard” or an “automatic,” or by their engine size, for example, a “V8” or “V6.”

Also, one note before we jump into raceways. This info applies mainly to casters with top plates versus stem casters. Stem casters have a pin that pokes up into the application. Top plates attach with screws and are more secure. There’s also less variation in the raceways of stem casters, which almost always happen to be swivel rigs.

TYPES OF CASTER RIGS: GENERAL

There are essentially two main types of raceways/rigs: a kingpin and a kingpinless. Both of these types refer to how the top plate and the rest of the caster are joined. One uses a rivet (kingpin), and the other uses ball bearings. There is also at least one main variation of the kingpin: the forged kingpin. Both the forged kingpin and the kingpinless can come in a maintenance-free version as well, depending on the choice of the manufacturer. So, you normally have four choices of rigs: a kingpin, a kingpinless, a forged kingpin, and a maintenance-free (either forged kingpin or kingpinless).

We’ll discuss the differences in these rigs, but think about caster wheels/rigs in these terms. What if your car tires only worked when driving around town, but then you decided to drive 75 miles per hour on the freeway? It wouldn’t be pretty. This is actually a reality with casters. Some casters will work in towlines, and others will not. So, what should you look for when deciding on a rig? Let’s take a look at the two main types of casters and then the two main variations.

KINGPIN CASTER RIGS

Pretty much all casters have had some sort of relationship with the kingpin caster, either as a variation or as a replacement. This is reflected in the name “kingpinless.” The “kingpin” in “kingpin casters” simply refers to the pin that connects the top plate to the raceway. The kingpin is essentially a bolt that keeps everything together and allows the rest of the rig to swivel around on it. With a “standard” kingpin caster, the kingpin is relatively small, compared to those normally found on “forged kingpin rigs.” The kingpin caster is the least expensive version of all casters and can be used in hand-pushed applications. A kingpin is the base level for all swivel casters.

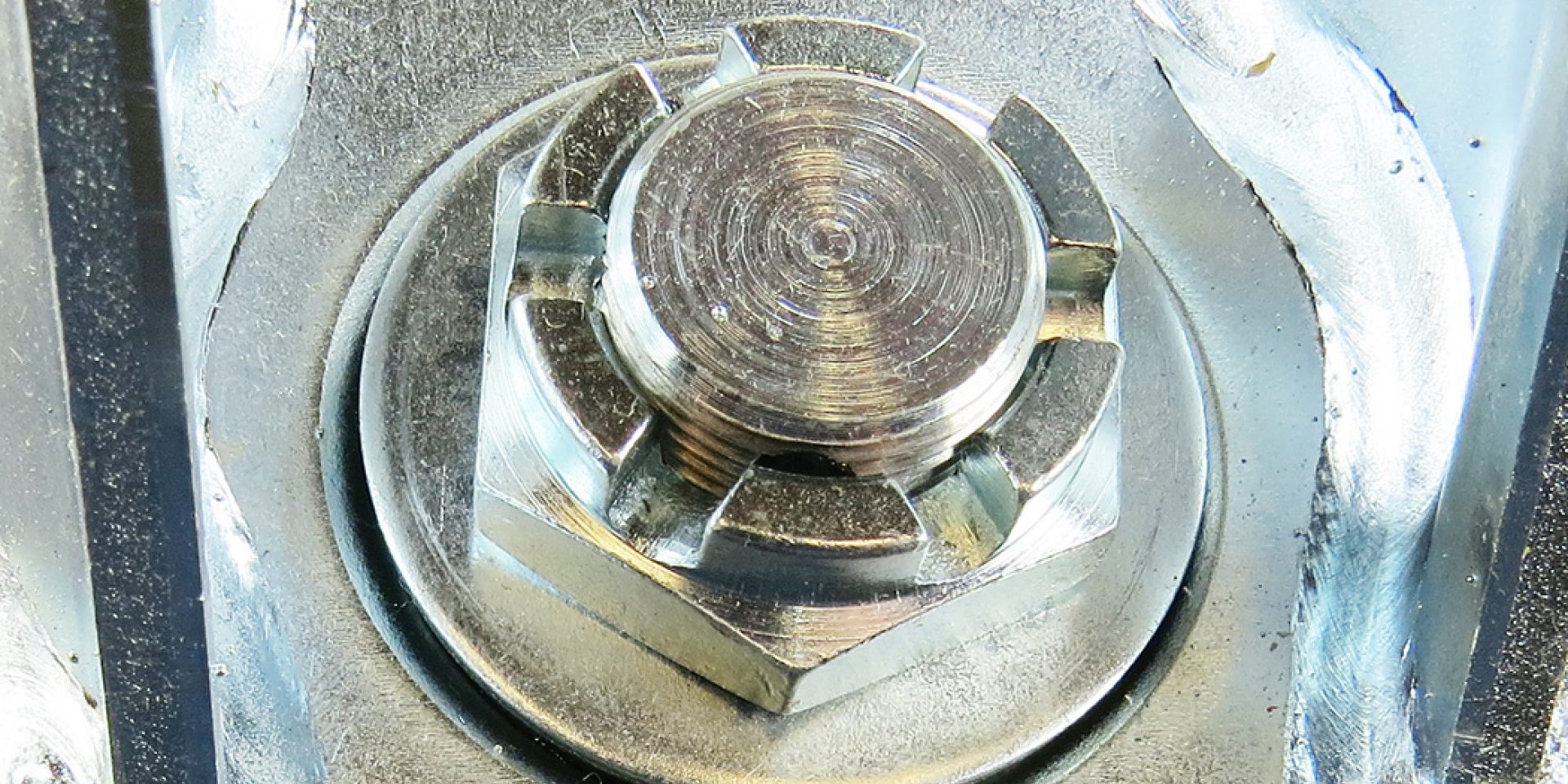

Kingpin caster connection to the top-plate:

The kingpin caster uses a kingpin to connect the raceways and the top plate. Essentially, a rivet (kingpin) acts as the axle around which the raceway/fork moves. This is a very simple and effective design. The strength of the rig is reliant on the strength of the kingpin itself. If the kingpin fails, so does the caster.

Kingpin caster maintenance:

Kingpin casters come with sets of ball bearings on which the caster can swivel around along with the kingpin. These ball bearings require grease in order to work optimally. For this reason, you’ll need to apply grease via a Zerk fitting.

Kingpin caster overall design and durability:

The overall design is simple, which is actually a good thing. However, a non-forged kingpin will lead to all sorts of problems ultimately, so if you have applications with towing or frequent movements with heavy loads, you need to look at another type of raceway/rig. This is because, over time, the kingpin will stretch, the kingpin will become loose, and the ball bearings will fall out. You don’t want a caster failing during a towline operation. You can also adjust some kingpin forks during the life of the caster to try and tighten things up (dependent on the manufacturer), but failure is still a real possibility in more demanding environments.

KINGPINLESS CASTER RIGS

The kingpinless raceway/rig was designed after the kingpin rig, as the name suggests. With a kingpinless raceway, there is no kingpin to fail. Rather, it uses ball bearings. This rig is an absolute upgrade from the standard kingpin rig and is much more versatile and varied in its uses. This is the starting point for towlines.

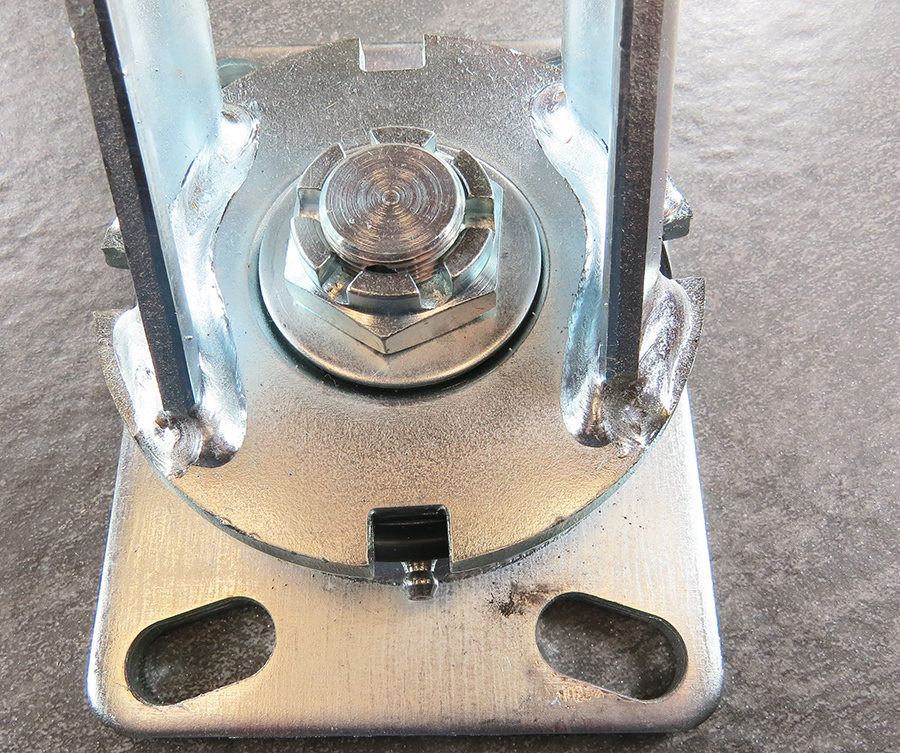

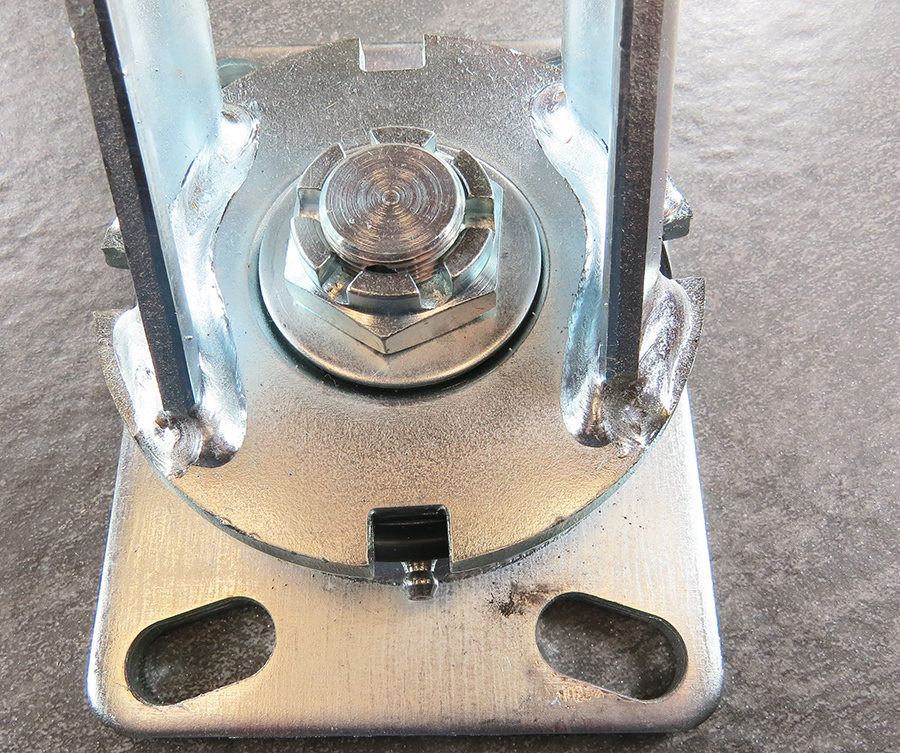

Kingpinless caster connection to the top-plate:

Instead of a kingpin, one cylindrical piece of metal slips over another smaller piece where they are connected with a groove. Then ball bearings are poured into this groove through a hole that is later sealed off. At this point, the two pieces are completely bound together by the ball bearings themselves and a hardened raceway for these ball bearings. Because of this, you get virtually no failure, compared to a standard kingpin.

Kingpinless caster maintenance:

A kingpinless rig most definitely requires greasing. You need to make sure that you are keeping enough grease in the rig for the bearings to work smoothly. Because the bearings play such an important role in durability and overall function, it is important that you stay on top of the overall maintenance of this rig.

Kingpinless caster overall design and durability:

You get exceptional value when you use kingpinless rigs, such as the CC Alpha or CC Armor. The ball bearings with the hardened raceway do a fantastic job of providing both great durability and smooth functionality for both towlines and manual push/pull applications. Essentially, you sacrifice nothing and gain advantages in money, time, and effort when you go with a kingpinless over a standard kingpin rig. You pay more initially, but in the end, you’ll be paying much less because the product will last longer and cause fewer maintenance issues. This is particularly true the more carts you have in your facility and particularly if tugging is involved.

VARIATIONS OF THE KINGPIN (FORGED)

Because the kingpin design is so simple, you’ll find some variations of the kingpin. Because of these variations, it’s important to know what type of kingpin you’re getting. You already know about the “standard” kingpin, but there is also a much more robust and higher quality version, a “forged” kingpin.

Forging of metal is the process of heating the metal and shaping it in that original form as opposed to casting, which forms the metal from a liquid state. Forging metal produces a more durable and overall better product. So, you get a better product in general with a forged kingpin.

This process with casters produces a caster with fewer separate parts. Metal sections that are normally connected with a standard kingpin are actually a completely whole piece of metal with a forged kingpin. The difference in quality couldn’t be greater. In general, this type of caster stands up to the rigors of a towline or heavy weight better than all other caster rigs/raceways.

Forged kingpins are also almost always much larger than a “standard” kingpin. So, not only do you have a forged kingpin, but you also have a kingpin that is many times the size of a “standard” kingpin. Obviously, you can imagine what a stronger and larger kingpin would offer you in terms of versatility, durability, and overall function.

Keep in mind that different companies offer different versions of the forged kingpin. Each company combines the forged kingpin with different bearing types and other design features. They also use the kingpin in subtly different ways, so not all forged kingpin casters are made alike.

Forged kingpin caster connection to the top-plate:

The forged kingpin caster uses a kingpin, just like with the “standard” kingpin. However, there is a huge difference; the kingpin is forged and much more robust and larger in general. For all intents and purposes, the forged kingpin is a completely different rig type.

Forged kingpin caster maintenance:

The maintenance requirements of these rigs depend on the model, but with models, such as the forged kingpin rig of CC Peak, the rig is completely maintenance-free. There is an initial greasing of the rig during the manufacturing process, but after this, the grease lasts as long as the rig’s life. This is not guaranteed with every brand and model, as it is with the CC Peak.

Forged kingpin caster overall design and durability:

Because of the large and robust kingpin, there is little to no failure of the kingpin. With this design, you get the simplicity of design of the kingpin but ultra-durability and, with the right model, extremely smooth movement. The CC Stark’s rig is a fantastic example of this. Because this rig type is so different from a conventional kingpin caster in general, you can use many forged kingpin rigs in towlines. In fact, models utilizing a forged kingpin are the best in the industry. You can also use these rigs with push/pull applications.

CC Stark Forged Kingpin Swivel Caster:

8" x 2" CC Stark Swivel Caster

SKU: CC-5160-800200-40-T2

ALT-SKU: CCSTARK-8S

-

- Overall Height

- 10-1/8"

- Wt. Capacity

- 2,000 lbs.

- Wheel Width

- 2"

- Wheel Diameter

- 8"

MAINTENANCE-FREE CASTER RIGS

Many forged kingpin and kingpinless rigs are also maintenance-free, but each company has different ways of achieving this, and not all rigs are equally as maintenance-free. The sealing process and a design that keeps your bearings/grease away from the elements will determine how maintenance-free your rig is.

Maintenance-free caster connection to the top-plate :

The maintenance-free caster rig is normally no different from a forged kingpin or a kingpinless rig, so the connection is simply how these accomplish this.

Maintenance-free caster maintenance:

You might have guessed that there is no maintenance with maintenance-free rigs. Really there is not much more to say here. You buy the rig, put it on your cart, and then forget that it is there because you don’t have to add any grease to the rig at all. That means no one has to periodically squirt grease into the Zerk fitting. So, essentially you’re dealing with no downtime for maintenance and no more grease.

Maintenance-free caster overall design and durability:

As stated above, the forged kingpin is simply a starting point for the design of many maintenance-free caster rigs, in addition to the kingpinless, but let’s concentrate on the forged kingpin. Take the rig of the CC Stark and the CC Peak. Each of these caster rigs uses the forged kingpin as its base, but they have different designs for different applications.

The CC Peak uses a thrust bearing for primary weight impact while also using tapered roller bearings. These tapered bearings are the bearings that you’ll find on automobiles to control for impact from the top, bottom, and sides. That means that you’ll have a much more durable and resilient piece of equipment, but you’ll also have a tremendously smooth and completely maintenance-free experience. The CC Peak will excel at most applications, but it really performs when ergonomics is at the center of the conversation. Immediately, you can see how smooth this rig is by spinning the top plate. This will translate into an optimal experience in all cases concerned with ergonomics.

CC Stark’s rig, on the other hand, has a subtly different sealing approach and still includes a Zerk fitting for greasing, if necessary. This rig has an incredibly robust design, even more so than the CC Peak. The kingpin is a monster. The steel is thick. While not as free-moving as the CC Peak, the rig is precision-crafted with the highest tolerances. The CC Stark wheel, with its rig, is the best caster for towlines on the market because of these precise qualities. This rig is designed for high weight at high speed. Applications where the rig will be taking real abuse are also perfect for this maintenance-free rig. When you have the most demanding environments (particularly in towlines), the CC Stark, with its forged kingpin rig, is the best option. If ergonomics is your primary concern, then a setup with the CC Peak rig is your maintenance-free choice.

You are now one of the elites when it comes to caster knowledge. You’ve mastered wheels, forks, brakes, leads, and now raceways. Each one of these components offers you many different ways to make a huge difference in your facility. Really, it’s easy; just get the best casters you can for your unique situation. Now, we’d love to chat with a fellow member of the caster elite. Just imagine the conversations we could have!

We’ve reduced companies’ caster spend by 50%.

With your new knowledge, we can do this together.

Get bulk discounts today!