5 Signs Your Greenhouse or Vertical Farm Needs an Upgrade

In the fast-growing world of controlled environment agriculture, mobility is not a luxury. It is essential. From rolling grow towers and mobile harvest carts to modular workstations, vertical farms and greenhouses depend on reliable movement to stay productive and adaptable.

But even the most advanced systems can underperform if the casters beneath them are worn out, mismatched, or low quality. If you are hearing squeaks, feeling drag, or seeing floor damage, your casters might be the weak link.

Here are five clear signs it may be time to upgrade. We will also cover how to choose the right solution.

1. Squeaking or Grinding When Equipment Moves

If your carts or towers produce a high-pitched squeal or grinding sound, it is more than just a nuisance. These sounds often signal worn bearings, corrosion, or lack of lubrication. This is especially common in humid, wet environments.

What to look for:

Casters with sealed, maintenance-free rigs are ideal for high-moisture settings. They keep water, grit, and chemicals out of internal components. This extends caster life while keeping your operation quieter and more efficient.

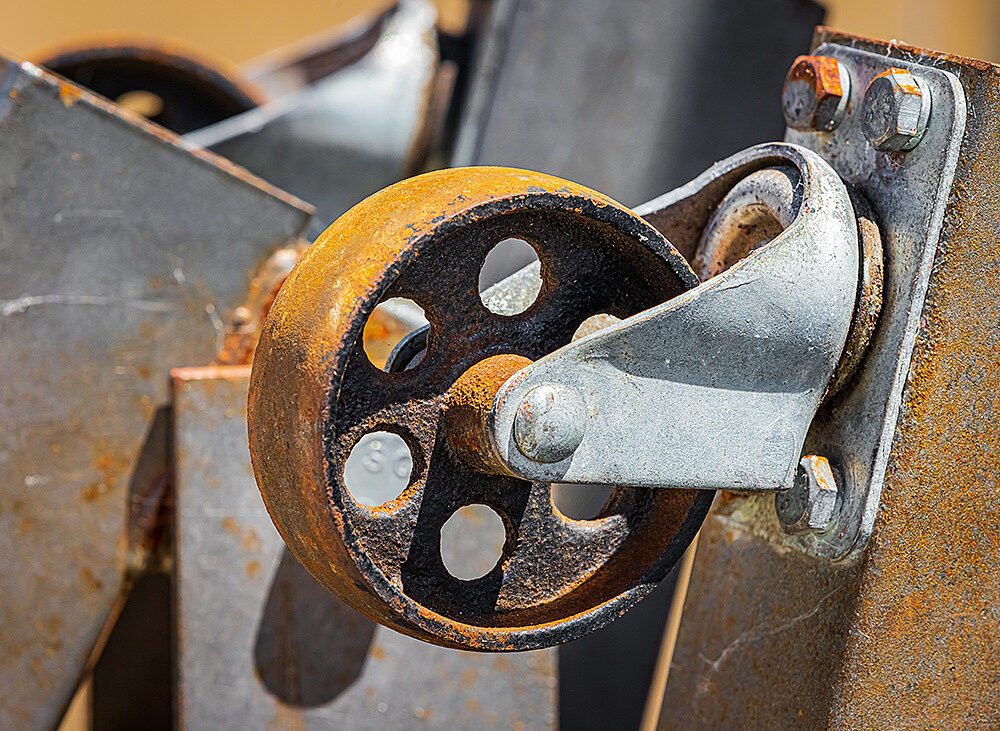

2. Rust or Corrosion on Caster Rigs

Rust on a caster is not just cosmetic. It is a sign that the structure is beginning to degrade. Moisture, cleaning agents, and fertilizer exposure can wear down untreated rigs quickly.

What to look for:

Stainless steel or zinc-plated rigs offer superior corrosion resistance. These materials hold up in washdowns and resist chemical exposure, protecting both your equipment and your team from unexpected failures.

3. Carts That Stick or Are Hard to Push

If it takes extra effort to move trays, racks, or harvest bins, your casters may be working against you. Flat spots, misalignment, and embedded debris all reduce rollability and increase the force required to move equipment.

What to look for:

Ergonomic casters with low rolling resistance reduce strain and improve efficiency. Look for tread designs that shed debris and roll easily over greenhouse flooring, even when conditions are damp or gritty.

4. Floor Scratches, Gouges, or Wear Patterns

Water, dirt, and aggressive tread materials can do serious damage to sealed concrete, epoxy, or tile floors. These surface issues increase slip risk and often lead to expensive repairs.

What to look for:

Choose casters with floor-safe treads such as soft rubber or polyurethane. These materials provide smooth, non-marking performance and reduce the risk of grinding or scraping sensitive floor coatings.

5. Strain, Trips, or Injuries Related to Cart Movement

Caster issues often become safety issues. Sticking wheels, unexpected jolts, or hard-to-push equipment can all contribute to worker strain or injury. This is especially true in fast-paced or high-volume environments.

What to look for:

Ergonomic caster solutions improve rollability and reduce push force. Focus upgrades on your heaviest carts or most frequently moved equipment to create a safer, more productive workspace.

One Bad Caster Can Ruin the Whole Setup

Even if most of your casters are performing well, a single worn or jammed wheel can cause instability, floor damage, or increased injury risk. If you notice wobbling, uneven wear, or inconsistent rolling, inspect the entire set. Replacing just one failing caster can prevent broader equipment issues.

Ready to Improve Mobility in Your Facility?

If any of these signs sound familiar, your casters may be holding your greenhouse or vertical farm back from operating at its best.

At Caster Connection, we offer high-performance caster solutions built to withstand the challenges of controlled agriculture. This includes resistance to humidity, washdowns, uneven floors, and heavy loads.

Request a free Caster Needs Eval with one of our Caster Nerds to explore options that match your facility, your workflow, and your safety goals.