What Are Ergonomic Casters?

By utilizing ergonomic casters, your company gains multiple advantages, including reduced injuries, increased savings, and enhanced productivity. In fact, you’re much more likely to keep ergonomic initiatives when you invest in ergonomic casters.

However, on the thousands of on-site visits we’ve had with our clients, we have noticed that initially they might think of casters like batteries or light bulbs, that is, like commodities. It is true that some horrible casters are commodities. They provide very few ergonomic benefits.

Using these casters in a quality business operation is a huge mistake. Employees are injured daily, and there is a huge cost associated with the injuries to these poor employees. Ergonomic casters literally make the difference between injury and productivity.

So, ask yourself this question, “Are my casters ergonomic casters, or are they putting my employees in danger?”

In this article, we’ll show you how you can tell the difference between good and horrible ergonomic casters before you buy them.

8" CC Nexus Kingpinless Swivel Caster with Extended Swivel Lead - 4" X 4-1/2" top plate

SKU: CC-2215-800200-40-T1

-

- Overall Height

- 9-1/2"

- Wt. Capacity

- 1,750 lbs.

- Wheel Width

- 2"

- Wheel Diameter

- 8"

8" CC Nexus Kingpinless Swivel Caster - 4" X 4-1/2" top plate

SKU: CC-2115-800200-40-T1

-

- Overall Height

- 9-1/2"

- Wt. Capacity

- 1,750 lbs.

- Wheel Width

- 2"

- Wheel Diameter

- 8"

8" CC Nexus Maintenance-Free Swivel Caster - 4" X 4-1/2" top plate

SKU: CC-3115-800200-40-T1

-

- Overall Height

- 9-1/2"

- Wt. Capacity

- 1,750 lbs.

- Wheel Width

- 2"

- Wheel Diameter

- 8"

6" CC Apex Kingpinless Swivel Caster

SKU: CC-2110-600200-40-T1

ALT-SKU: CCAPEX-6S-KP

-

- Overall Height

- 7-1/2"

- Wt. Capacity

- 1,000 lbs.

- Wheel Width

- 2"

- Wheel Diameter

- 6"

6" CC Apex Extended-Lead Kingpinless Swivel Caster

SKU: CC-2210-600200-40-T1

ALT-SKU: CCAPEX-6S-KP-EXT

-

- Overall Height

- 7-1/2"

- Wt. Capacity

- 1,000 lbs.

- Wheel Width

- 2"

- Wheel Diameter

- 6"

6" CC Peak Maintenance-Free Swivel CC Apex Caster

SKU: CC-3110-600200-40-T1

ALT-SKU: CCAPEX-6S-EMF

-

- Overall Height

- 7-1/2"

- Wt. Capacity

- 1,000 lbs.

- Wheel Width

- 2"

- Wheel Diameter

- 6"

8" CC Apex Kingpinless Swivel Caster

SKU: CC-2110-800200-40-T1

ALT-SKU: CCAPEX-8S-KP

-

- Overall Height

- 9-1/2"

- Wt. Capacity

- 1,200 lbs.

- Wheel Width

- 2"

- Wheel Diameter

- 8"

8" CC Apex Kingpinless Swivel Caster with Extended Swivel Lead

SKU: CC-2210-800200-40-T1

ALT-SKU: CCAPEX-8S-KP-EXT

-

- Overall Height

- 9-1/2"

- Wt. Capacity

- 1,200 lbs.

- Wheel Width

- 2"

- Wheel Diameter

- 8"

8" CC Peak Maintenance-Free Swivel CC Apex Caster w/ Extended Swivel Lead

SKU: CC-3210-800200-40-T1

ALT-SKU: CCAPEX-8S-EMF-EXT

-

- Overall Height

- 9-1/2"

- Wt. Capacity

- 1,200 lbs.

- Wheel Width

- 2"

- Wheel Diameter

- 8"

ERGONOMIC CASTER WHEEL QUALITIES:

CASTER WHEEL MATERIAL

The material of the caster is incredibly important. Imagine a wheel made of Jell-O versus a wheel made of stone.

Each wheel would work differently. You’re not going to find wheels made of these materials, but the extremes illustrate how a variation in a formulation can change the qualities of the caster wheel material.

That’s really all we’re looking for, qualities, and the vast majority of the time, nylon and polyurethane provide us the features we need, although there are other materials as well.

There are also huge differences in qualities and formulations of polyurethane and nylon. So, what qualities differ between specific formulations of materials of nylon and polyurethane?

DUROMETER

Durometer is the measure of how hard the material is. In general, you want your material to be as hard as possible because the harder the material, the easier you can roll your cart.

Keep in mind that there are a bunch of other factors that will affect your ability to roll your cart. You can’t just go buy a caster made of solid steel and expect it to perform well without a little thought first.

Some of the factors that will limit your ability to use a hard wheel include the amount of debris, the presence of impediments (bumps, potholes, lips), the need to preserve the floor (a hard wheel beats up your floors), the need for silence and grip, and the need for variety of applications (push/pull and towlines).

In other words, we increase our durometer as high as we can, while maintaining the best qualities we can for the unique application.

REBOUND RESILIENCE

So, if we could increase the durometer but still have some of the qualities mentioned above, we would have an ideal caster wheel.

That’s where rebound resilience comes into play. Rebound resilience is essentially the polyurethane’s ability to bounce or spring off of the ground. You can test this very easily as you can see here.

Rebound resilience separates a good caster from a horrible caster. You can have a lower durometer to navigate over debris and still be used in towlines, but still increased push/pull because the rebound resilience springs the wheel off of the floor.

CASTER WIDTH AND DIAMETER

Basically, the larger the diameter, the easier your cart rolls. You’re only limited by the dimensions of your carts and space available in your facility.

The width is adjusted according to the amount of weight that your cart normally carries. The more weight you need, the wider your caster will be, so basically you need to play with each caster diameter and width for the weight and size restrictions found with each application.

CASTER SHAPE AND DESIGN

The shape of the tread surface greatly affects how ergonomic your caster will be. When you have a rounder caster tread, your wheel touches less of the surface.

This is the case only when you have no weight on the wheels. When you add weight, the wheel begins to compress and flatten.

If you add too much weight, the tread will flatten completely, and then you have to rely on the quality of the material (polyurethane, nylon, etc.), and not the tread shape.

For this reason, a rounded or donut tread is a more ergonomically designed caster for weights around 2,500 and below, depending on the durometer.

Weights above this with a donut tread are normally compressed to the point that you no longer can take advantage of the smaller surface area for easier pushing and pulling, unless you adjust the diameter and/or durometer.

Because of this, you can have ergonomic casters with a flatter tread at higher weights, such as the CC Stark.

The other way you can modify the caster tread is by splitting it, that is, to have two thin wheels used in place of one integral tread. This splitting is referred to as a split tread.

The split tread has only come around in the last few years. The problem with the split tread is that you have a very difficult time utilizing the rounded tread, because you have split right down the center of the donut tread.

This means that you get more friction and that you have higher push/pull. For this reason, an “integral” tread is better for ergonomics. A great example of a fantastic ergonomic caster with an integral donut tread is the CC Apex.

ERGONOMIC RIG QUALITIES:

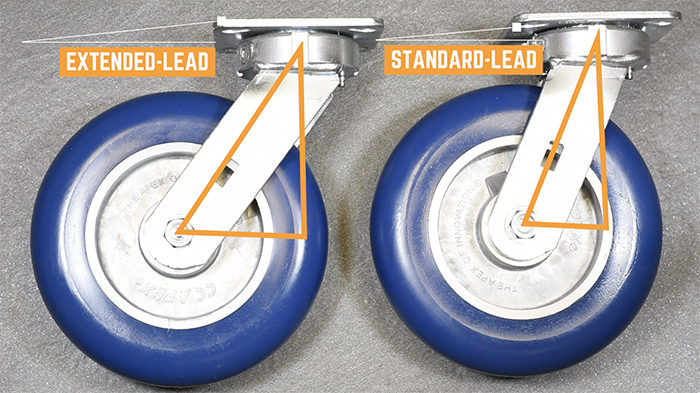

CASTER LEAD

For ergonomics, you want an extended lead. Lead is essentially the angle of the fork. An extended lead is a sharp angle of the fork.

This allows the caster to move much more efficiently and effortlessly, when the wheel is at a variety of different angles. So, this one is easy; get an extended lead.

CASTER RIG QUALITY AND DESIGN

The quality and design of the bearing is incredibly important for how smooth the rig is. Multiple types of bearings allow the rig to move smoothly in different directions. Thrust and roller bearings are great options for an ergonomic caster.

There are many qualities of rigs that you should look at, but you need a maintenance-free/sealed rig if you want to have a quality ergonomics experience.

A sealed rig keeps dirt, salt, ice, and everything else out of the bearings and allows you to push your cart easily for many years.

If the bearings get debris into them, the rig will not move well anymore. There are other qualities of a rig that affect longevity, but the lead and bearings (sealed) are the most important for ergonomics. A perfect example of this type of a rig is the CC Peak.

Need help with implementing ergonomic casters?

Get Rolling with Caster Connection →