Caster Swivel Lead Explained (Video)

WHAT IS LEAD AND WHAT ARE THE MOST IMPORTANT TYPES

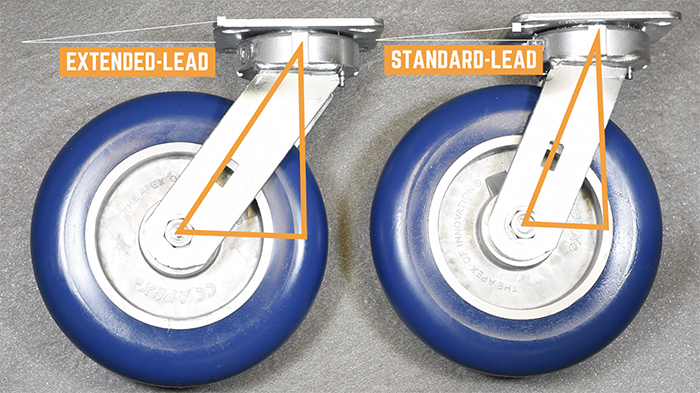

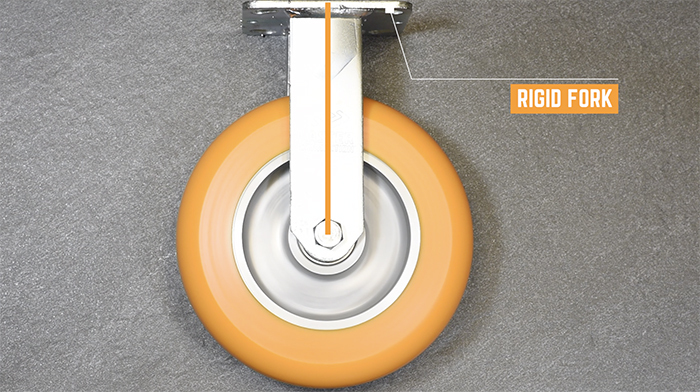

Before we talk about lead (actually swivel lead), we need to mention fork types. A caster’s fork holds the wheel and axle and connects these to the top plate. Many types of devices with wheels have forks, such as bikes, for example. With casters, there are really three types of forks: rigid, standard-lead, and extended-lead. Rigid is simple; it is a fork that is 90 degrees from the point at which the wheel hits the ground.

Caster lead is found almost exclusively on swiveled casters.

With the other two, a standard-lead and extended-lead, we have to understand lead before we can talk about them. Caster swivel lead is the measurement from the center of the swivel to the wheel’s vertical centerline. With a rigid fork, there is no lead (zero lead), because these two lines are the same. So, when you change the angle of the fork, you have a difference between these two centerlines. Now, we have a lead. You may recognize that motorcycles and bikes have leads. Think about a chopper.

With casters, there is no bible when it comes to leads. There is a smaller angle (and therefore smaller lead) that is referred to as a “standard-lead,” but this can vary slightly from manufacturer to manufacturer. A general measurement on 8-inch wheels is about 1 ½ to 2 ¼ inches (1.5” – 2.25”). Now, you can increase the angle, and therefore the lead. This is an “extended-lead”. With an 8-inch wheel, you’re looking at around 2 ¾ to 3 ½ inches (2.75” – 3.5”) on the lead. So, when talking about casters, you essentially are dealing with two leads, standard and extended.

With bikes of all sorts, they play with this angle to fine-tune your riding experience, but in the caster industry, we see mainly these two types, besides rigid. These are mainly found on swivel casters. So, what does changing the lead actually do?

RIGID FORKS AND ZERO LEAD

Before we answer that, think about strength. A rigid fork, with its zero lead, is the strongest because the weight pushes directly down on the fork. The bigger the lead is, the less weight you can carry. A rigid fork allows us to support the most weight. When we get into more extreme situations with extended-leads, we need to compensate with thicker forks and more robust raceways on the caster at times, so we can normally adjust different parts of the caster to offset the drop in weight. The fact remains, though, that extended-leads are not capable of carrying as much weight as standard-leads or rigid forks. You need to make sure you understand this for your application.

If we can adjust parts of the rig, at times, to compensate for the dropped weight capabilities, what is the main purpose of rigid forks? An important reason is because of the different maneuverability options we have when we combine different types of forks/rigs. It is much easier to maneuver swivel rigs than rigid ones. However, rigid rigs help you to stay on track and in a straight line, so we need to balance the two. See examples of caster wheel arrangements here.

Another feature of rigid forks is that they have the smallest turning radius of all forks. When you extend the lead, your turning radius increases. So, when we’re concerned with making sharp turns or stacking carts in close proximity, we need to make sure that our turning radius won’t impact this. This is important for both manual and powered applications. With this in mind, we can examine what advantages you get with an extended rig.

EXTENDING THE LEAD

When we extend the lead, we need to remember that this doesn’t solve all of our problems. It gives us choices, but we need to use the proper caster lead to the proper application. With this in mind, here is how you will be affected when you change the lead of your casters.

Now, a regular standard-lead is of course extended from a rigid, but you really gain the most benefits when you go to a true extended-lead. For example, when you use an extended-lead, it will almost always immediately reduce push/pull by 10 to 50 percent. You, in one moment, reduce the chance of injury to your employees who are pushing or pulling carts, in addition to extending the life of all of your equipment. How does an extended-lead accomplish this?

We exert the greatest amount of effort when we push the cart initially. An object remains in motion easier than it begins this motion. Wheels are also almost always turned when at rest, that is, not in the trailing position. You have to push the cart to straighten these wheels out. In other words, everything’s stacked against you when you push the cart initially. Extended-lead casters allow the wheels to easily swing into position so that you don’t have to slip a disc in your back every time you want to get those thousands of pounds moving.

https://giphy.com/gifs/2jve2KY...

This smooth start with the extended-lead also reduces strain on the entire caster itself. There is no grinding or catching, so you will extend the life of your caster. That means less downtime and less maintenance but also more productivity and time for you.

As noted, an extended-lead moves the wheel to the trailing position much easier. It also allows your cart to track (move in a straight line) much easier as well, reducing caster flutter. This is very important in general, particularly if any high speeds or towline applications are involved. Imagine that cart at the supermarket that no one wants because of the wobbly wheel. Do you want your expensive product that weighs thousands of pounds on a cart like that? Extending the lead will get rid of this tendency in most cases. Again, your product will be protected because you won’t have a shaking cart, and your employees won’t have to worry about an unstable cart. You can imagine how important this is for towlines and high speeds. You also bring in the benefits of not having to use more resources, pulling a cart that is difficult to pull because of wobble. Finally, you’ll reduce noise dramatically because you won’t have any flutter or parts that have come loose because of this constant shaking and fluttering. If you have dozens of carts, we are talking about a major reduction in noise, but even if you have only one cart, your cart will be as quiet as a mouse.

Now that you understand leads, what do you do with the info? If you already have carts and casters, take a look and see how many of them have extended-leads. If many of them do not, you might need to look into adding more extended-leads. If you have extended-leads, do the raceway and fork provide you with enough strength. If you haven’t ordered them yet, then make sure to match the fork, raceway, and wheel properly to give yourself the best and most trouble-free experience possible.

Our job is to make your life easy. We’ve helped people for over 30 years with casters, and we’d love to do the same for you. If you’d like help, let us know here. Otherwise, feel free to learn from our videos and articles. We want you to enjoy the best situation possible either way. We know that casters aren’t as exciting as bikes and motorcycles, but hey, we can’t remember the last time a bike moved 3,000 pounds.