CC APEX ESD

CASTER CONNECTION'S

- SAME VERSATILITY AS THE CC APEX BUT WITH ELECTROSTATIC DISSIPATING ELEMENTS

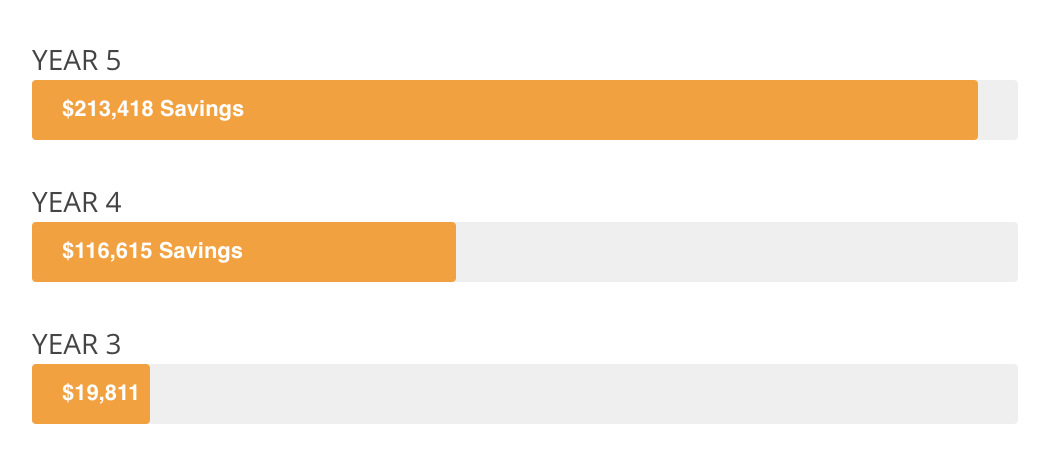

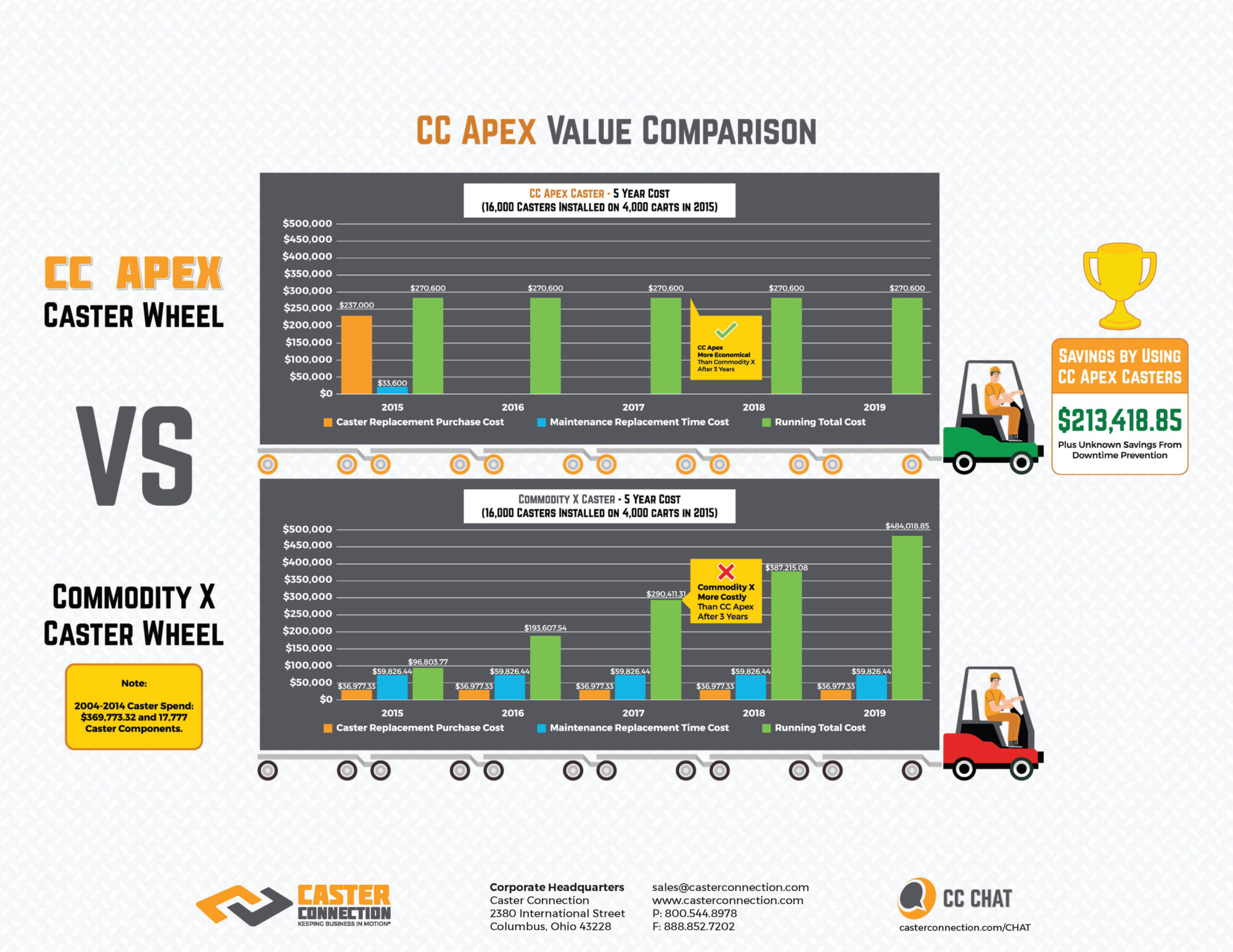

- SAME HUGE ROI OVER COMMODITY CASTERS AS THE ORIGINAL CC APEX

CC Apex ESD (electrostatic dissipating) wheels offer the same ergonomic, noise-reducing, and durability qualities as the original CC Apex but add the benefit of being electrostatic dissipating throughout the wheel tread.

CC Apex ESD carries weight loads of 400-1,200 lbs.

Ideal industries:

- Electrical/Electronic Manufacturing

- Healthcare

- Industrial/Mechanical Engineering

- Material Handling

- Utilities

Applicable Uses

- Electrostatic Dissipation Necessary

- Debris Issues

- Ergonomic Concerns

- Floor Protection

- Noise Reduction

- Push/Pull Reduction

- OEM Equipment

- Safety

- Towlines

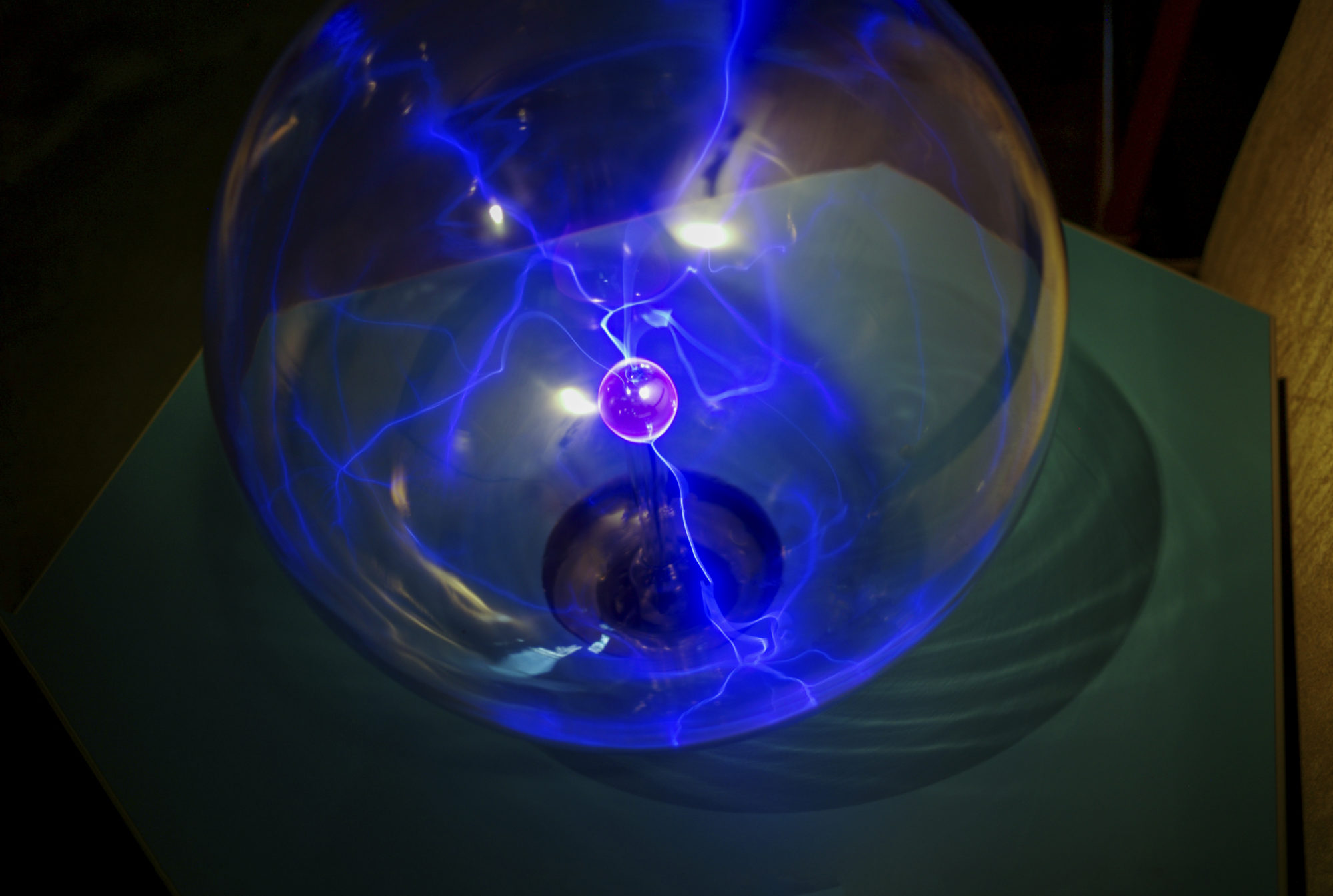

As carts move around in any facility, they generate static electricity when there is no path for this electricity to dissipate. When this electricity is transferred from one object to the next, we call this electrostatic discharge. This discharge is extremely damaging in a variety of ways.

This discharge completely ruins valuable electrical components. It potentially ignites gases. It also affects clean rooms and medical areas by causing dust to cling together, which impeded it from entering filtration systems. At the same time, it can cause plastics to cling together, slowing production.

The CC Apex ESD uses compounds completely distributed throughout the polyurethane to allow electrons to not collect and therefore create static electricity. Because of this, you're protected from the serious complications that electrostatic discharge causes.

What is Electrostatic-Dissipative Material?

Electrostatic dissipative material conducts electricity, with a surface resistivity of equal to or greater than 10^5 ohms, but less than 10^12 ohms. This material is prescribed for discharge-safe areas because it allows static electricity to flow through the caster wheels and into conductive flooring. It is highly recommended that all casters on a cart (or other fixture) in an electrostatic discharge-safe area are electrostatic dissipative so that they can optimally contact conductive flooring.

SAME VERSATILE CASTER AS THE CC APEX PLUS EXTRA PROTECTION AGAINST ELECTROSTATIC

The CC Apex ESD Does It All

With the CC Apex ESD, you get a caster that is versatile enough to be used in most facilities from automotive production lines to data centers. The wheel comes in a variety of sizes, and has top notch electrostatic dissipating elements added into the polyurethane. This means that you have world-class ergonomics, noise reduction, debris resistance, towline performance, and protection in electronic/chemical applications.

QUALITIES OF THE CC APEX ESD (QUALITY AND RESILIENCE)

- Caster dissipates electrostatic

- Caster springs off the ground: better push/pull

- Caster navigates over obstructions and debris

- Caster repels debris from collecting

- Caster does not flat-spot

- Caster dampens sound

- Caster grips floor

- Caster lasts substantially longer

HOW THESE QUALITIES TRANSFORM YOUR OPERATIONS

- Your facility and products are producted from electrostatic damage

- You are protected from injury & loss of money

- You can work without interruption

- You preserve your floor and avoid costly repairs

- You don't have to transfer the load for storage

- Your valuable hearing is protected

- You avoid injury and damage in towlines

- You have huge ROI benefits