Difficulty In Measuring Push/Pull

Casters are one of the best ways to improve ergonomics, and everyone in the caster industry talks about “push/pull.”

It is one of the primary ways that we as a company differentiate ourselves from other caster companies.

We use this measurement to improve working environments for our customers to prevent injury to their valued employees and to avoid downtime and the extremely high costs associated with it.

When we develop a caster, compare a caster, or focus on a part of a caster, we need to make sure that we know the difference in push/pull so we can quantify the improvements we’ve made.

However, as engineers and caster experts, we recognize a little secret in measuring push/pull; it is extremely difficult to get consistently accurate and comparable measurements because there are a lot of factors that can influence the results.

In fact, the results can vary from situation to situation greatly. So, if the measurements on push/pull vary so much, how can we even use them to measure improvements?

We give our best recommendations below.

WHY MEASURING PUSH/PULL IS DIFFICULT

THE DEVICE

So, what makes measuring push/pull so difficult? First, we need to consider the device used to measure push/pull.

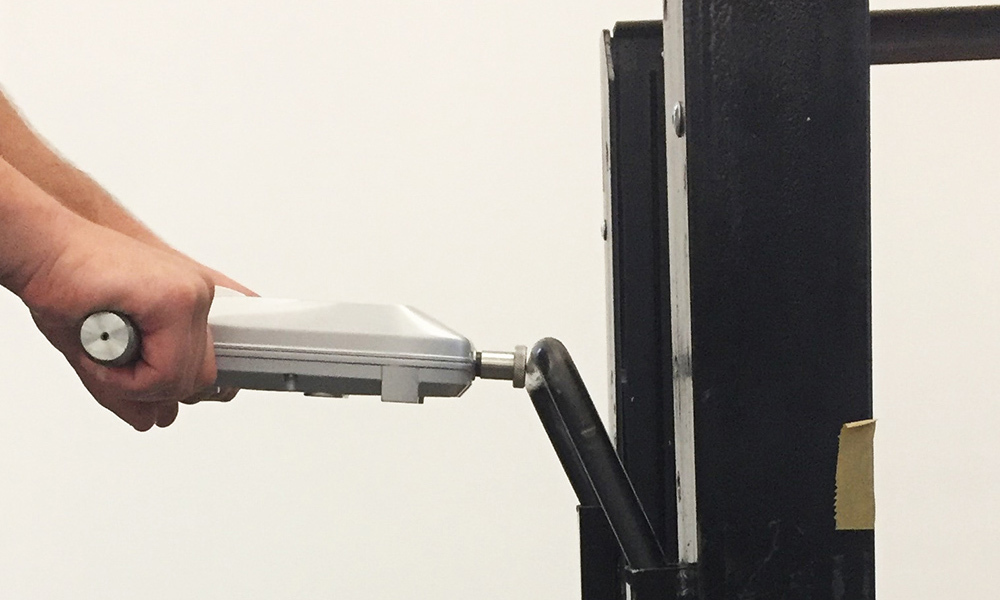

Almost every single company out there uses a digital force gauge. This gauge is reasonably priced and does a fairly good job of measuring the force exerted during the pushing and pulling motions.

It uses a very thin point to measure the force exerted on the cart. This can cause some problems, however.

The measurement can vary depending on the angle at which the gauge makes contact with the cart. The optimal angle is 90 degrees.

Any variance from this angle from test to test will skew the results either up or down.

So, if this angle varies from test to test, you’ll have inaccurate data that may lead you to false conclusions and disadvantageous actions, like purchasing the wrong casters, for example.

THE PERSON CONDUCTING THE TEST

The nature of the gauge leads the person conducting the test to make this error. The person conducting the push/pull test can make other errors as well.

The speed, smoothness, and force that a person uses will greatly affect the push/pull measurements.

Let’s say that person A pushes on the gauge very quickly and erratically, and then person B tests another caster by pushing slowly and smoothly.

Each of these measurements will be very different. We’re talking possibly over 10 pounds of variance between these two people.

DISTANCE MOVED IN TIME

Part of what contributes to this variance is the distance moved in a given time. Person A above will more than likely move a greater distance in a given time frame than person B.

Because of this variance in distance, the readings on the gauge will be quite different from person to person.

This will affect your ability to make informed decisions with your ergonomic options and may lead to an injury to your employees because of poor testing procedures.

TEMPERATURE

Another factor that affects your push/pull readings is temperature. The material consistency of the caster wheel varies with the temperature tremendously.

With cold temperatures, the wheel is harder. With warm temperatures, the wheel is softer. Why does this matter?

Well, if you work with caster wheels, you might know that the durometer (hardness of the wheel) greatly affects how well a caster will move.

The harder the wheel, the easier it will move, and therefore, the better push/pull it will have. There are definitely other factors, like rebound resilience, that affect this, but durometer is a huge factor in ergonomics.

If the temperature is cold, the harder the wheel is, and if the temperature is hot, the softer the wheel is. If you’re on the equator, you might not have to worry about this, but for most people, this is not the case.

Temperature will make a huge difference in your push/pull results.

SURFACE VARIENCE

You don’t realize how uneven floors often are until you start doing push/pull tests consistently. We all think the ground is relatively even, but many floors are uneven throughout.

Also, some floors will even have slight depressions that will require more force on your casters to push or pull through.

Of course, every floor that your casters will actually be used on are like this too, but when you’re measuring one caster against another to make informed comparisons, floor unevenness will skew your measurements quite a bit.

At the end of the day, all of these factors can combine to make your measurements extremely inaccurate.

If a person pushes a cart with a steep angle on the gauge, slowly and smoothly over a small distance, on a cold day, and on a slight decline, then the results will be skewed in one direction.

You might make a huge purchase based off of these horribly inaccurate measurements. So, how can you make better and more consistent push/pull measurements?

BEST PRACTICES FOR MEASURING PUSH/PULL

USE A MACHINE

The best way to get perfect measurements is to use a machine to take the measurements. The machine can take into consideration all or most of the factors that will skew or change push/pull measurements.

The problem is that most companies cannot afford, or have not invested in, a machine to perform these measurements. So, for most people, this isn’t a practical option.

USE A TRANSDUCER

The same thing goes for the use of a transducer (force plate), which is more accurate and cuts down on the variability of the push/pull gauge. Most companies don’t use a transducer, because of the price and/or lack of priority of using a transducer.

However, even if you don’t use either of these two options, you can still improve the consistency of your push/pull measurements.

SAME PERSON

Whenever you conduct a push/pull test, always have the same person do the tests. The person will probably perform the tests in a similar fashion, so even if the external factors vary, the results will be relatively consistent.

You can at least compare results performed by the same person on different casters, even though you shouldn’t compare the results taken from a different source/person, since these results are based on too many variables including the person who performed the testing.

SAME DISTANCE AND SURFACE AREA

Next, you should measure out a space and mark the starting and endpoints. This will assure that you have traveled the exact same distance when you conduct tests between different casters.

This will also guarantee that you are conducting the tests with the same surface area. The surface area might not be the most ideal, but at least the results will come from the same distance and same surface area.

REGULATED TEMPERATURE

When you measure from the same location over the same distance, this will help you to be in an environment that has the same temperature as well, but to be extra careful, plan on doing your tests on one day that has consistent temperatures.

For example, don’t choose a day that will be warm early in the day but drop in temperature because of a rainstorm later that day.

If you have a highly temperature regulated room, then this isn’t as much of a problem, but in many factories, the temperatures vary greatly depending on the weather.

MONITORING THE TIME

Finally, pushing a cart at the same speed and exertion is very important. To get more consistent, time yourself to make sure that you are moving from one marker to the next.

This can be done through trial and error, or if you’re really hardcore, you can use a metronome to make sure that you are moving at the right rhythm.

Pay close attention to the first foot or two since this is where you’ll encounter the most resistance.

By following these guidelines and being mindful of the challenges, you’ll gain much more consistent measurements.

This will allow you to make more informed decisions and more accurately compare casters of different brands and qualities.

You can be more confident that you are investing your money into the best caster and not making a costly error by buying the wrong casters for your ergonomic needs.

We’ve also taken this one step further and have collaborated with The Ohio State University Spine Research Institute.

The OSU SPI has been a leader in the industry and has established the best guidelines for push/pull.

Starting in 2019, it has also been conducting scientific tests using our casters to establish guidelines behind push/pull testing and to aid the people who perform these tests.

To read more about this collaboration, follow this link to an article or click on the button below to talk with us.

We have over 30 years of ergonomics and push/pull experience, and we’d be happy to help you out with any need you might have.

THERE'S NO REASON TO SOLVE YOUR PUSH/PULL CHALLENGES ALONE! CLICK HERE FOR AN ERGONOMICS EXPERT